Leave Your Message

Request a Quote

As we approach 2026, the demand for effective Bag Filters continues to rise. According to a recent industry report by Global Filtration Solutions, the market for air and liquid filters is projected to grow by 7% annually. This trend illustrates an increasing focus on environmental sustainability and clean air initiatives.

Industry expert Dr. Emily Carter emphasizes, "Investing in high-quality Bag Filters is crucial for enhancing system efficiency and ensuring regulatory compliance." The need for better filtration solutions is clear. Many industries, including manufacturing and pharmaceuticals, are prioritizing performance and reliability.

However, the market features a variety of Bag Filters, each designed for specific applications. Not all filters perform equally, and some might not meet stringent standards. Consequently, businesses must evaluate their unique needs carefully. Choosing a suboptimal filter can lead to higher costs and inefficiency. As we move forward, realizing the potential of advanced Bag Filters could mark a significant step towards improved operational success.

Bag filters play a critical role in various industries, including manufacturing, pharmaceuticals, and food processing. They help control air pollution by capturing dust and particulate matter. This is essential for maintaining a safe and clean working environment. Effective filtration enhances product quality and ensures compliance with environmental regulations. However, not all filters are created equal. They differ in their efficiency, lifespan, and maintenance needs.

In manufacturing, bag filters are vital for removing harmful particles from the air. They can affect worker health and machinery performance. A clogged filter can lead to decreased efficiency. Regular monitoring is essential to avoid costly downtimes. Maintenance can be overlooked, leading to performance issues. It’s crucial to choose filters that suit specific operational requirements.

In the pharmaceutical industry, bag filters ensure product purity. Contaminants can compromise safety. This industry demands high standards and rigorous testing. Yet, implementing these standards may require additional resources and training. The importance of proper filter selection cannot be overstated. Filters affect production quality and operational costs. Each decision in this area has significant implications.

| Filter Type | Application | Efficiency (%) | Typical Lifespan (Months) | Material |

|---|---|---|---|---|

| Synthetic Fiber | Dust Collection | 99.9 | 12 | Polyester |

| Cellulose Fiber | Air Filtration | 95 | 6 | Cellulose |

| Glass Fiber | Industrial Processes | 99.9 | 24 | Glass |

| PTFE Membrane | Chemical Filtration | 99.5 | 18 | PTFE |

| Activated Carbon | Odor Control | 90 | 12 | Carbon |

When evaluating bag filters for 2026, certain criteria must be prioritized. Filtration efficiency is critical. Look for filters that can capture smaller particles. High-efficiency filter media can lead to better air quality. However, the trade-off can be increased pressure drop. This could affect overall airflow. Therefore, balance efficiency and pressure is essential.

Next, consider the material of the filters. Different materials serve different purposes. Some are designed for dust, while others handle smoke or chemicals. Be aware of the environment where these filters will be used. Longevity is another significant factor. A filter that lasts longer can save costs. Yet, durability shouldn't sacrifice performance. Regular maintenance can often be overlooked. It's vital to schedule updates for optimal results.

Finally, assess the ease of installation and replacement. Complicated systems can lead to costly downtime. User-friendly designs promote efficient use. Compatibility with existing systems is also important. Many times, a “one-size-fits-all” solution doesn’t truly fit. Reflection on these criteria will guide you towards making better choices in 2026.

When choosing bag filters for 2026, consider various brands and models based on their performance. Some of the best in the market focus on airflow and filtration efficiency. These factors make a noticeable difference in industrial settings. You want a model that fits your specific needs. Always check the filter material and design for durability.

Moreover, it's essential to assess maintenance requirements. Filters that are easy to install can save time. Models may vary in price, but higher cost doesn’t always equal better performance. It’s wise to look for user reviews and product specifications. Understanding the average lifespan of filters also helps in planning replacements.

While some filters excel in efficiency, they may not offer versatility. It’s frustrating when products don’t perform as advertised. Reflecting on personal needs can guide better choices. Not all bag filters are created equal. Subtle differences in design may lead to considerable differences in function. Always keep an eye on trends and innovations for the best selection.

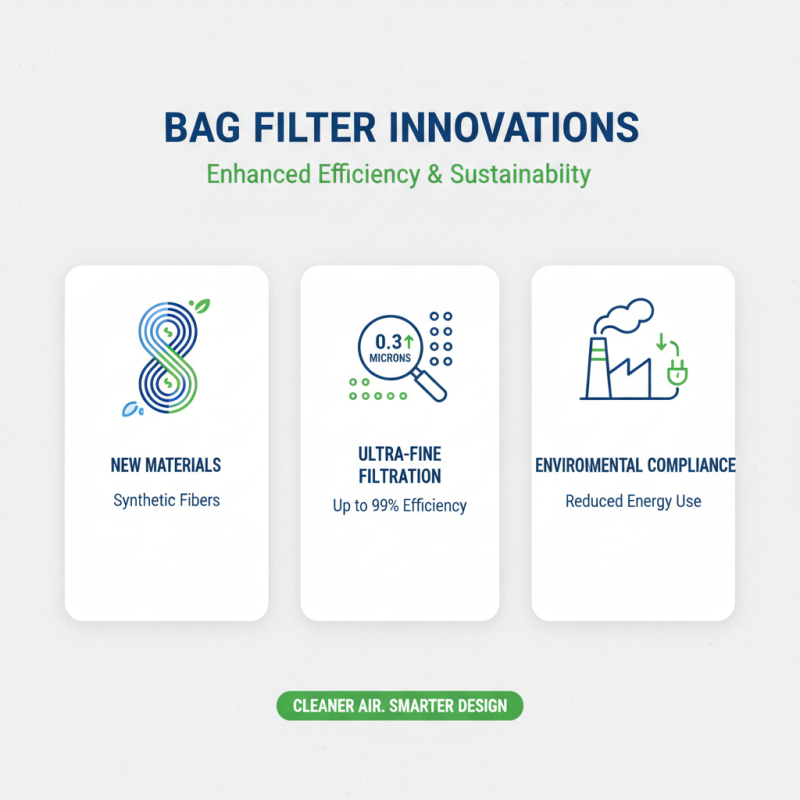

In recent years, bag filter design has seen significant innovations. Advances in materials have shifted to synthetic fibers that enhance filtration efficiency. Reports indicate that these new materials can capture particles as small as 0.3 microns with up to 99% efficiency. Such performance meets stringent environmental regulations while reducing energy consumption.

Additionally, smart technology integration plays a crucial role in bag filters. Sensors can monitor pressure drops and filter conditions in real time. This technology allows for predictive maintenance, which minimizes system downtime. A study suggests that implementing these smart technologies can reduce operational costs by 15%.

Despite these innovations, challenges remain. For instance, the initial investment for advanced bag filters can be high. Not all facilities can afford this upgrade. Furthermore, as industry demands grow, ensuring reliability and efficiency remains a concern. It requires ongoing research and adaptation to emerging needs in various sectors, including industrial and commercial applications.

When selecting bag filters, environmental considerations are crucial. The filtration industry is gradually moving towards sustainable options. For instance, a recent report by the Filter Media Association revealed that eco-friendly filters can reduce waste by 30%. This statistic highlights the need for better materials in filter production.

Using recycled materials can significantly lower carbon footprints. Many manufacturers are exploring this avenue. A study showed that filters made from recycled content performed comparably to traditional options. However, challenges remain. Not all recycled materials meet quality standards, leading to potential inefficiencies.

Incorporating biodegradable elements is another consideration. Some bag filters can break down naturally after disposal. Their impact on landfills can be reduced significantly. Still, industry experts warn that costs can be higher. This poses a dilemma for companies balancing sustainability and budget constraints.

With growing awareness, dialogue continues. The future of bag filters must integrate both performance and environmental responsibility.