Leave Your Message

Request a Quote

Choosing the right Bag Filtration system can be challenging. With various options available, it is crucial to understand your specific needs. According to Dr. Emily Carter, a leading expert in Bag Filtration technology, “Selecting the best system requires a clear understanding of your operational goals.” Her words resonate deeply in the industry.

Different applications demand distinct filtration solutions. For instance, a manufacturing facility might need a system that handles larger particulate matter. Meanwhile, a food production line may prioritize sanitary conditions above all. Visualizing your environment can aid in making the right choice. It’s not just about purchasing; it’s about matching the system to your requirements.

However, mistakes can happen. Some may choose a Bag Filtration system based solely on cost, overlooking efficiency. Reflect on the long-term impacts of such decisions. Investing in the wrong technology can lead to higher maintenance costs and lost productivity. Understanding these factors helps in navigating this complex landscape while ensuring quality output.

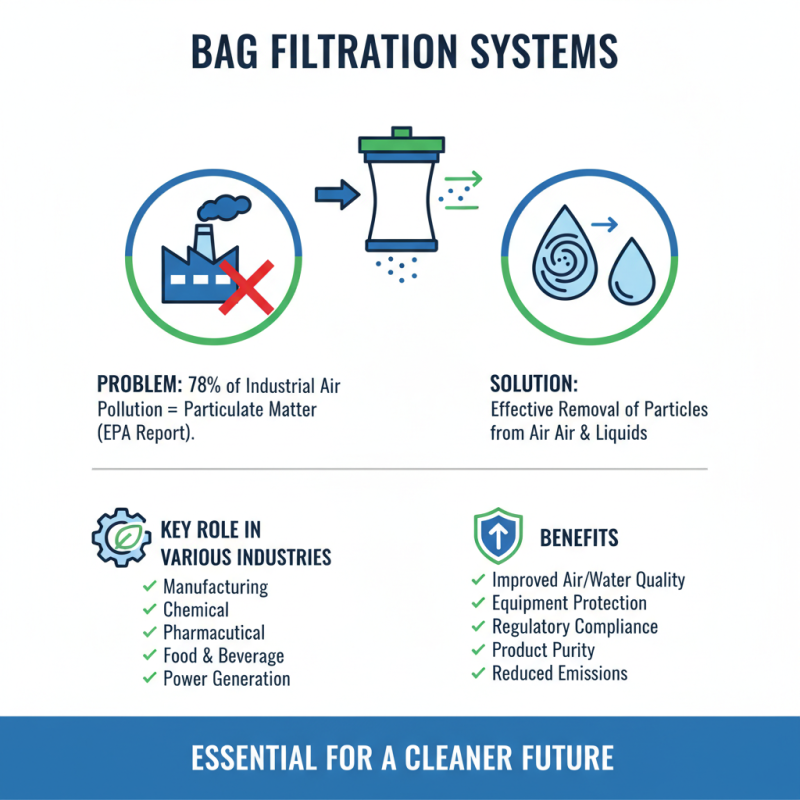

Bag filtration systems play a crucial role in various industries. They effectively remove particles from air or liquids. A report by the Environmental Protection Agency indicates that around 78% of industrial air pollution comes from particulate matter. Therefore, the right filtration system is essential.

Consider the specific needs of your operation. For example, high dust loads may require systems with larger bag capacities. According to research from the American Filtration & Separations Society, systems with larger filter areas capture more particles and provide longer service life. However, maintenance can be challenging. Often, dirty filters need frequent replacement, leading to increased costs. Opting for lower maintenance systems might seem appealing, but can they handle heavy loads?

One common oversight in selecting bag filtration systems is failing to assess airflow requirements. Inadequate airflow can hinder performance. The ideal system should balance filtration efficiency and energy consumption. Data suggests that poorly matched systems can lead to a 30% increase in operational costs. Understanding your system's needs is critical for optimal performance. Lack of attention to these details can lead to inefficiency and increased expenses.

Choosing the right bag filtration system is crucial for effective air quality management. There are several key factors to consider when making this decision. One important aspect is the filtration efficiency. A study from the U.S. Environmental Protection Agency indicates that a filter with a high MERV (Minimum Efficiency Reporting Value) rating can capture up to 95% of airborne particles. However, higher efficiency may also mean greater resistance to airflow.

Another crucial factor is the type of application. For instance, industrial settings often have different requirements compared to residential spaces. A report from the American Society of Heating, Refrigerating and Air-Conditioning Engineers suggests that bag filters designed for high dust-loading environments need to accommodate larger particles while maintaining airflow. These filters can be more expensive but may ultimately reduce maintenance costs.

Cost and lifespan also play significant roles. It’s essential to consider the initial investment versus the long-term savings from fewer replacements. Some systems may require more frequent changes, leading to hidden costs. Reflecting on these choices can help ensure the right balance between performance and budget. Effective filtration is about understanding your specific needs and finding a system that meets those requirements without overspending or compromising on air quality.

| Factor | Description | Importance Level |

|---|---|---|

| Airflow Rate | The volume of air that can pass through the filter system, measured in CFM (cubic feet per minute). | High |

| Filtration Efficiency | The percentage of particles removed from the air stream (typically ranging from 70% to 99.9%). | Critical |

| Bag Material | Different materials offer various levels of durability and filtration capabilities. | Medium |

| Dust Load | The amount and type of dust particles that the filter will be expected to handle over time. | High |

| Maintenance Requirements | How often the filter needs to be replaced or cleaned, impacting ongoing costs. | Medium |

| Size and Space | The physical dimensions of the bag filtration system and the available installation space. | Medium |

| Cost | Initial purchase price and long-term operational costs, including maintenance. | High |

Bag filtration systems come in various types. Each type serves different applications. One common type is the woven bag filter. These are effective for separating solids from liquids. They are often used in food and beverage industries. Their design allows for easy cleaning and replacement.

Another option is the needle felt bag filter. This type captures finer particles. It is suitable for various industrial processes, including chemical manufacturing. However, these filters may require more maintenance. Users need to regularly check for clogs and replace filters.

Consider your specific needs when choosing. For instance, think about the flow rate and the size of particles you want to filter. Some systems may perform well under certain conditions but not others. Reflect on where the system will be used. This can greatly influence performance. Selecting the right filter can ensure efficiency.

When selecting a bag filtration system, efficiency is paramount. Efficiency refers to how well the system removes contaminants from the air or liquid. Factors to consider include particle size, flow rate, and material compatibility. A system that performs well in laboratory tests may not deliver the same results in actual environments. Always assess real-world performance data if possible. This can reveal discrepancies between theoretical benefits and practical applications.

Maintenance is another critical aspect. Bag filters require regular inspection and replacement. Neglecting maintenance can lead to decreased performance and unexpected downtime. Consider the accessibility of the filters for replacement and cleaning. Some systems are easier to maintain than others. If maintenance is overlooked, efficiency will suffer. Ask users about their experiences regarding upkeep. This feedback can provide valuable insights for informed decisions. Balancing efficiency and maintenance needs is crucial. It can make or break your filtration system’s effectiveness in the long run.

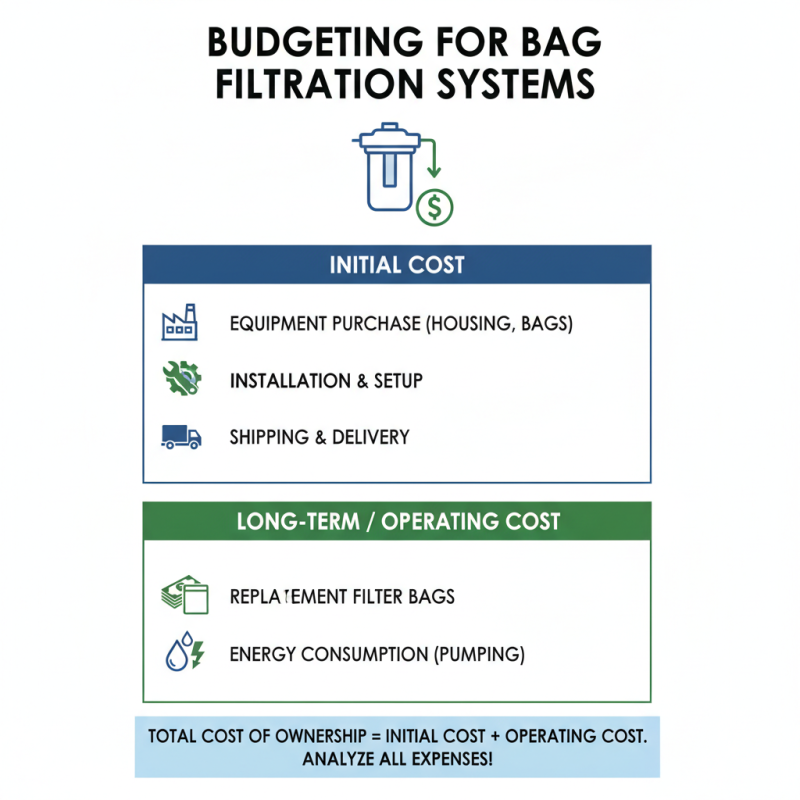

When budgeting for a bag filtration system, you must consider various factors. The initial cost is essential but not the only factor. Maintenance costs can add up over time. It’s wise to analyze these expenses thoroughly.

One important tip is to list all potential costs. This list should include filters, replacement parts, and energy consumption. Add a buffer for unexpected repairs. Sometimes, the lowest upfront price leads to hefty maintenance fees.

Another aspect to consider is your specific usage needs. If your filtration demands are high, a basic model may lack efficiency. This can lead to higher operational costs. Think about your long-term needs before deciding. Don't rush into purchases based only on price. Reflect on how often you'll need to replace equipment.

Ultimately, it’s about balance. An affordable system might seem appealing but can be costly in the long run. Investing a bit more initially may save you significant funds later. Be sure to review all aspects before making your choice.