Leave Your Message

Request a Quote

Choosing the right pump diaphragm is crucial for the efficiency and longevity of your pumping system. The pump diaphragm plays a significant role in determining the performance characteristics of various pumping applications, ranging from fluid transfer to chemical processing. Understanding the specific requirements of your application, such as the type of fluid being pumped, operating pressures, and temperature ranges, is essential in making the right selection.

Additionally, the materials used in the construction of pump diaphragms can greatly impact their performance. Factors such as chemical compatibility, durability, and wear resistance should be carefully considered to ensure optimal functionality. By evaluating these elements, you can make informed decisions that will enhance the overall effectiveness of your pumping system and prevent potential failures. In this guide, we will explore the key considerations in selecting the appropriate pump diaphragm tailored to your specific needs, ensuring smooth operations and maintenance-free usage.

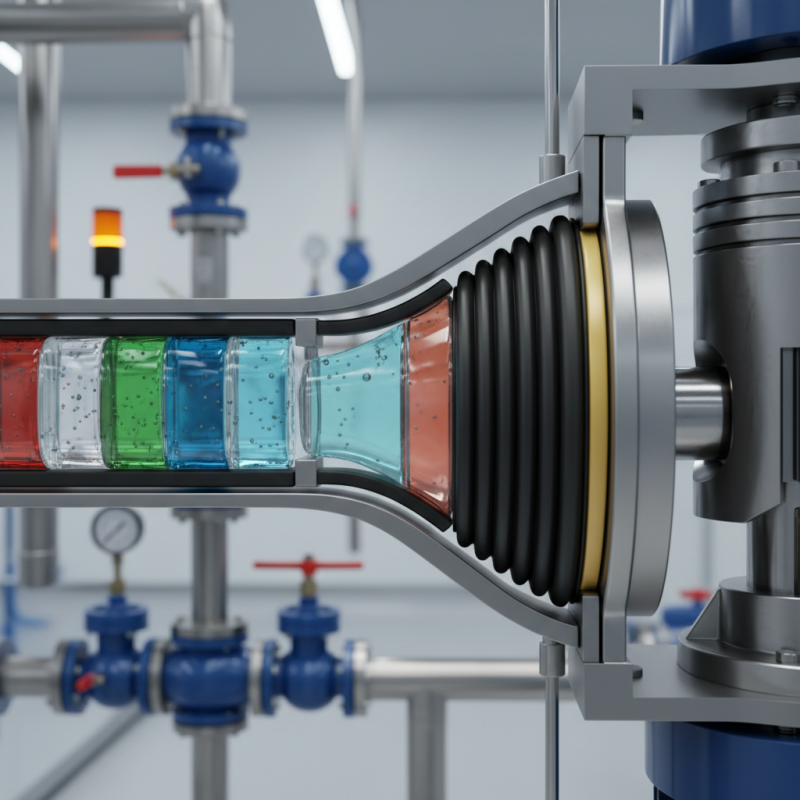

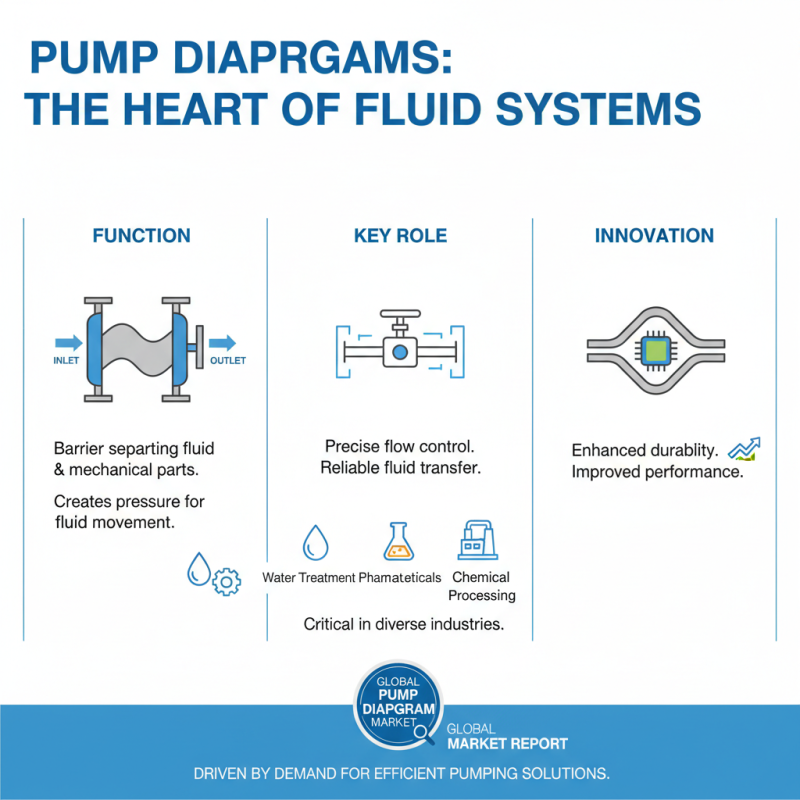

Pump diaphragms play a crucial role in fluid systems, acting as barriers that separate the working fluid from the mechanical components of the pump. Their primary functionality involves creating pressure changes to move fluids effectively within a system, particularly in applications requiring precise flow control. According to a report by the Global Pump Diaphragm Market, the increasing demand for efficient and reliable pumping solutions across various industries, such as water treatment, pharmaceuticals, and chemical processing, has propelled innovations in diaphragm technology, resulting in enhanced durability and performance.

Understanding the materials and construction of pump diaphragms is vital for optimizing their functionality. Common materials include nitrile, neoprene, and PTFE, each offering different advantages in terms of chemical resistance and operational temperature ranges. A recent study indicated that diaphragm failure can lead to up to 30% downtime in industrial operations, underscoring the importance of selecting the right diaphragm tailored to specific application needs. Proper material selection, combined with knowledge of operating conditions, such as pressure fluctuations and fluid characteristics, can significantly improve system efficiency and reduce maintenance costs over time.

When selecting the right pump diaphragm for your application, it is crucial to identify the specific requirements driven by the nature of the fluid being transported. For instance, consider factors such as chemical compatibility, temperature, pressure, and flow rate, as each can significantly affect the diaphragm's performance and lifespan. According to industry reports, diaphragms made from materials like PTFE and EPDM are favored in applications involving corrosive and abrasive fluids due to their impressive resistance properties and durability. Understanding these requirements allows for a strategic approach to diaphragm selection, ensuring optimal operation and minimizing downtime.

Tips: Always conduct a compatibility test for the diaphragm material against your fluid to avoid premature failure. Additionally, consider the diaphragm’s elasticity and mechanical properties under varying pressure conditions, as these factors can impact the overall efficiency of your pumping system.

Another essential aspect is evaluating the operating environment. If the diaphragm will be exposed to extreme temperatures or pressure fluctuations, it is vital to select a diaphragm specifically designed to handle such conditions. Research indicates that diaphragms designed to maintain their integrity under thermal cycling can significantly enhance overall system reliability. By aligning the diaphragm choice with environmental parameters, you can improve performance and extend service life.

Tips: Review the manufacturer’s specifications and test data related to temperature and pressure limits before making a selection. Always account for potential system variations that may affect diaphragm performance over time.

This bar chart illustrates the durability ratings of different diaphragm materials, which is a crucial factor to consider when selecting a pump diaphragm for your specific applications. Each material's performance can greatly influence the efficiency and longevity of the pumping system.

When selecting a diaphragm for pump applications, it is crucial to consider the material's properties, as they significantly affect the efficiency and longevity of the pump system. One of the primary factors influencing diaphragm material choice is the type of fluid being pumped. For instance, corrosive chemicals may require materials such as PTFE or other specialized elastomers that can withstand aggressive environments. Conversely, non-abrasive fluids might allow for the use of more cost-effective materials without compromising performance.

Another key consideration is the temperature and pressure conditions under which the pump operates. High temperatures may necessitate materials that retain their elasticity and structural integrity, such as reinforced elastomers or high-performance polymers. Additionally, the operational pressure can influence the thickness and overall durability of the diaphragm. Therefore, it's essential to analyze the specific conditions of each application to choose a diaphragm material capable of providing optimal performance and reliability over time.

Proper material selection not only enhances efficiency but also minimizes maintenance and replacement costs, making it a critical aspect of pump system design.

When selecting the right pump diaphragm for your application, it's essential to understand the various types of diaphragms available and their performance characteristics. The most common types include elastomeric, thermoplastic, and metallic diaphragms. Elastomeric diaphragms, typically made from materials like nitrile or EPDM, are known for their flexibility and resistance to a wide range of chemicals. Reports from the Fluid Power Industry Council indicate that elastomeric diaphragms can handle pressures up to 150 psi, making them suitable for moderate industrial applications.

On the other hand, thermoplastic diaphragms offer excellent chemical resistance and longevity. Their performance characteristics shine in applications involving aggressive fluids or extreme temperatures, often allowing for operation in environments reaching up to 200°F. According to the Chemical Engineering journal, thermoplastic diaphragms have been shown to reduce maintenance costs by approximately 30% in specific sectors due to their resistance to wear and tear. Lastly, metallic diaphragms, while more expensive, are utilized in high-stakes environments requiring extreme pressure resistance, often exceeding 1000 psi, making them ideal for aerospace or pharmaceutical applications.

Choosing the appropriate diaphragm type involves weighing these factors against the specific demands of your application, such as operating pressure, fluid compatibility, and the environmental conditions they will face. Understanding these nuances can significantly enhance the efficiency and longevity of your pumping system.

| Diaphragm Type | Material | Temperature Range (°C) | Chemical Compatibility | Typical Applications |

|---|---|---|---|---|

| PTFE | Polytetrafluoroethylene | -50 to 200 | Excellent | Chemical processing, pharmaceuticals |

| EPDM | Ethylene Propylene Diene Monomer | -40 to 120 | Good (not compatible with petroleum oils) | Water treatment, food processing |

| Nitrile | Acrylonitrile Butadiene Rubber | -30 to 100 | Good (especially for oils) | Hydraulic applications, fuel handlers |

| Santoprene | Thermoplastic Elastomer | -40 to 130 | Good | Medical devices, water applications |

| Viton | Fluoroelastomer | -15 to 200 | Excellent (highly resistant to oils and chemicals) | Chemical processing, aerospace |

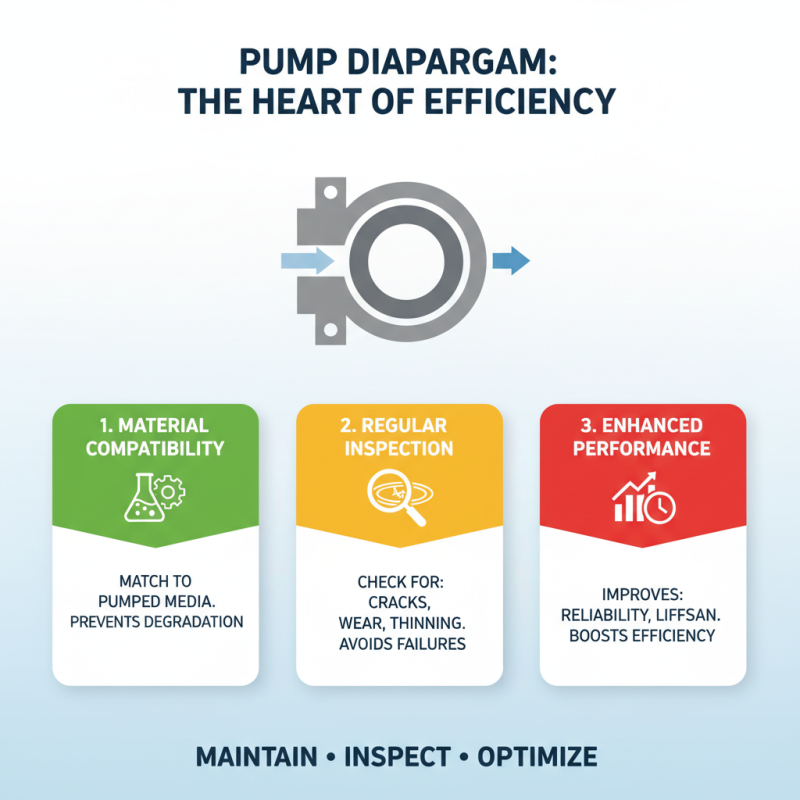

When it comes to maintaining operational efficiency in pumps, the diaphragm plays a crucial role. Regular inspection and maintenance of pump diaphragms can significantly enhance performance and extend the lifespan of the equipment. One key aspect to consider is the material of the diaphragm, as it should be compatible with the pumped media to prevent degradation. Additionally, regular checks for wear and tear, such as cracks or thinning areas, will help identify issues before they lead to costly failures.

Tips: Always maintain a clean operating environment for your pumps. Contaminants can accelerate wear and damage diaphragms, leading to unexpected shutdowns. Implement a routine cleaning schedule to remove any debris around the pump area.

Another consideration is the environment in which the pump operates. Temperature fluctuations and exposure to harsh chemicals can negatively impact diaphragm performance. Ensure that the diaphragm you choose is designed to withstand these conditions. Furthermore, establishing a proactive maintenance plan that includes periodic replacements based on usage patterns can help mitigate any risks associated with diaphragm failure.

Tips: Maintain detailed operational logs to monitor the performance of the diaphragm over time. This can provide invaluable insights on when to schedule maintenance or replacements, ensuring your pump operates efficiently at all times.