Leave Your Message

Request a Quote

When it comes to selecting the ideal equipment for your fluid handling requirements, the choice of a diaphragm pump can significantly influence the efficiency and effectiveness of your operations. Understanding what diaphragm pumps are and how they function is crucial for making an informed decision. These versatile devices utilize a flexible diaphragm to create a pumping action, offering a wide range of advantages, such as self-priming capabilities and the ability to handle aggressive chemicals and viscous fluids. However, with various types and models available on the market, it can be overwhelming to determine which diaphragm pump will best suit your specific needs. In this blog, we will explore five essential tips that will guide you in making the right choice, ensuring optimal performance while meeting your operational requirements. Whether you are in industrial, agricultural, or other applications, selecting the appropriate diaphragm pump can lead to enhanced productivity and cost efficiency.

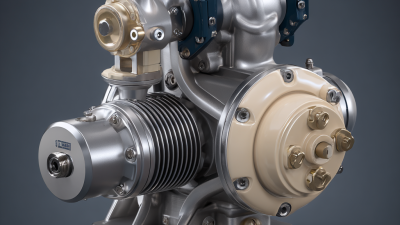

Diaphragm pumps are vital in various applications, ranging from chemical transfer to water treatment. Understanding their basic structure and functionality is crucial before making a selection. These pumps operate by utilizing a flexible diaphragm that creates a pumping action, effectively drawing in and expelling fluids. Their ability to handle abrasive, viscous, and even shear-sensitive fluids makes them an excellent choice for many industries.

When choosing a diaphragm pump, consider the specific medium you'll be handling. For instance, if you're dealing with corrosive liquids, opt for pumps made from chemically resistant materials. Additionally, assess the flow rate and pressure requirements of your application. Tip one: always match the pump's specifications to your operational needs to ensure efficiency.

Another important factor is the diaphragm material. Different materials, such as rubber or PTFE, provide varying levels of durability and compatibility. Tip two: select a diaphragm that best fits the chemical properties of the fluids being pumped. This choice can greatly affect the pump’s longevity and performance. By understanding these basics, you can make an informed decision that enhances productivity and reliability in your operations.

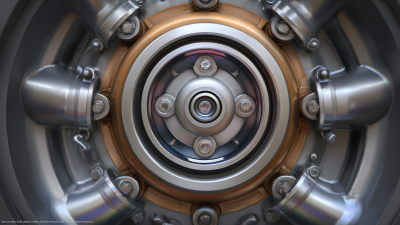

When selecting the right diaphragm pump, understanding your flow rates and pressure requirements is crucial. The flow rate, usually measured in gallons per minute (GPM) or liters per minute (LPM), determines how much fluid the pump can move efficiently. According to the Hydraulic Institute, maintaining optimal flow rates ensures the pump operates within its best efficiency point (BEP), minimizing wear and maximizing lifespan. For instance, if a process requires a flow rate of 50 GPM but the pump can only handle 45 GPM efficiently, the pump may struggle, leading to increased energy consumption and potential damage.

Additionally, evaluating pressure requirements is equally important. Diaphragm pumps operate effectively in pressure ranges typically between 1 to 100 psi for most applications. As indicated by a report from the American Society of Mechanical Engineers, operating outside this pressure range can lead to performance inefficiencies. Choosing a pump that meets or slightly exceeds your maximum pressure requirement can provide a buffer, allowing for system variations or blockages without overstressing the equipment.

When considering these factors, it is essential to match the pump's specifications with your application's unique demands. Always consult manufacturer data sheets and conduct thorough testing to ensure compatibility with your system's flow and pressure needs.

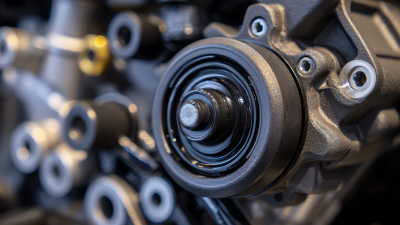

When selecting a diaphragm pump, ensuring material compatibility is vital for both longevity and safety. It directly affects the pump's performance and its ability to withstand various operational environments. For instance, many materials used in diaphragm pumps can be susceptible to corrosion or degradation when exposed to aggressive substances. Assessing the chemical resistance of materials, much like researchers do in evaluating automotive components exposed to biobutanol, is essential. This ensures that the pump's components will not fail prematurely and that they can maintain their functionality over time.

Moreover, considering compatibility goes beyond just chemical interactions. It also involves understanding the mechanical stress the materials will face during operation. As with advancements in composite materials in other applications, choosing the right mix of materials for diaphragm pumps can lead to significant improvements in performance and durability. By prioritizing this compatibility assessment, users can facilitate smoother operations and reduce the risk of costly repairs or replacements in the future.

This chart illustrates the compatibility of different materials used in diaphragm pumps with various fluids. Understanding these interactions is crucial for ensuring longevity and safety.

When selecting a diaphragm pump, energy efficiency and cost considerations play a pivotal role in ensuring the system meets operational demands while keeping expenses manageable. One key factor to assess is the pump's energy consumption rate, which directly impacts both operating costs and environmental footprint. Pumps designed with advanced technology, such as variable speed drives, can adjust their performance based on real-time needs, leading to significant savings in energy usage over time.

Additionally, while the initial purchase price of a diaphragm pump is important, it is essential to evaluate the total cost of ownership, which includes maintenance, operational efficiency, and lifespan. Investing in a high-quality, energy-efficient pump may incur higher upfront costs but can offer substantial savings in the long run through reduced energy bills and fewer maintenance requirements. By carefully considering these factors, businesses can choose a diaphragm pump that aligns with their budgetary constraints while optimizing performance and sustainability.

When selecting a diaphragm pump, maintenance and support are critical factors that directly influence long-term reliability. A well-maintained diaphragm pump can last significantly longer, often exceeding three to five years of operational efficiency when proper servicing protocols are adhered to. This is particularly important in industries where uptime is critical, as the total cost of ownership can be drastically affected by unplanned maintenance or downtime. In fact, studies have shown that businesses can save up to 30% of their operational costs by investing in quality maintenance programs for essential equipment, including diaphragm pumps.

Moreover, choosing a supplier that provides comprehensive support is vital. Many experts suggest that having access to technical support and replacement parts can mitigate potential disruptions in production. Reports indicate that nearly 70% of pump failures are attributed to improper installation or lack of support services, emphasizing the importance of selecting a vendor that not only sells the equipment but also offers continual training and support. As industries pivot toward more sustainable practices, integrating reliable diaphragm pumps into energy-efficient systems can enhance operational effectiveness, reflecting recent trends in distributed energy systems where reliability is paramount.