Leave Your Message

Request a Quote

Choosing the right Nanofiltration Filter is crucial for optimizing water treatment systems tailored to specific needs. According to a recent report by the International Water Association, the global water treatment market is projected to reach $800 billion by 2025, underscoring the increasing demand for efficient filtration technologies. Nanofiltration, positioned between reverse osmosis and ultrafiltration, effectively removes divalent ions and larger molecules while allowing monovalent ions to pass through, making it ideal for applications such as softening hard water and removing organic contaminants. Additionally, the Membrane Technology and Research (MTR) indicates that the implementation of nanofiltration can reduce water treatment costs by up to 30% compared to traditional methods. Therefore, understanding the specific characteristics and performance of different nanofiltration filters is essential for achieving optimal water quality and operational efficiency in various industrial and municipal settings.

Choosing the right Nanofiltration Filter is crucial for optimizing water treatment systems tailored to specific needs. According to a recent report by the International Water Association, the global water treatment market is projected to reach $800 billion by 2025, underscoring the increasing demand for efficient filtration technologies. Nanofiltration, positioned between reverse osmosis and ultrafiltration, effectively removes divalent ions and larger molecules while allowing monovalent ions to pass through, making it ideal for applications such as softening hard water and removing organic contaminants. Additionally, the Membrane Technology and Research (MTR) indicates that the implementation of nanofiltration can reduce water treatment costs by up to 30% compared to traditional methods. Therefore, understanding the specific characteristics and performance of different nanofiltration filters is essential for achieving optimal water quality and operational efficiency in various industrial and municipal settings.

Nanofiltration is an advanced water treatment technology that operates between ultrafiltration and reverse osmosis. It utilizes a semi-permeable membrane to effectively remove divalent ions, organic compounds, and larger particles while allowing monovalent ions and smaller molecules to pass through. This selective process makes nanofiltration particularly advantageous for treating water with variable quality, as it can enhance water purity without imposing excessive energy demands typically associated with reverse osmosis.

Nanofiltration is an advanced water treatment technology that operates between ultrafiltration and reverse osmosis. It utilizes a semi-permeable membrane to effectively remove divalent ions, organic compounds, and larger particles while allowing monovalent ions and smaller molecules to pass through. This selective process makes nanofiltration particularly advantageous for treating water with variable quality, as it can enhance water purity without imposing excessive energy demands typically associated with reverse osmosis.

One of the key advantages of nanofiltration is its ability to minimize the need for chemical additives. By using this method, facilities can achieve effective removal of contaminants, including hardness and color, while reducing the reliance on traditional coagulants or flocculants. Additionally, nanofiltration systems generally require lower operational pressures compared to reverse osmosis, leading to longer membrane life and lower maintenance costs. This combination of efficiency and effectiveness makes nanofiltration a preferred choice for various applications, including water softening, wastewater treatment, and food and beverage processing.

When selecting a nanofiltration filter for water treatment, the first step is to assess the specific quality of your water. This involves conducting a thorough analysis of the water source to identify contaminants such as hardness, nitrates, and organic compounds. Understanding the concentration levels of these contaminants is crucial, as it informs which type of nanofiltration technology will be most effective. For instance, if your primary concern is removing divalent ions like calcium and magnesium, a filter designed for mineral reduction would be ideal.

In addition to identifying contaminants, it’s essential to define your treatment goals. Are you looking to soften water, remove dissolved solids, or enhance taste? Each goal may require different filter specifications and capabilities. Additionally, consider the desired flow rate and system lifespan, as these factors impact the overall efficiency and cost-effectiveness of the treatment. By clearly understanding both the water composition and treatment objectives, you can make an informed decision on the right nanofiltration filter to address your specific needs effectively.

| Water Quality Parameter | Common Contaminants | Treatment Goals | Recommended Nanofiltration Type |

|---|---|---|---|

| Total Dissolved Solids (TDS) | Salts, Minerals | Reduce TDS levels | Low-pressure Nanofiltration |

| Hardness | Calcium, Magnesium | Softening water | Nanofiltration with specific membranes |

| Organic Compounds | Pesticides, Herbicides | Remove harmful organics | Thin-film composite membranes |

| Microbial Contaminants | Bacteria, Viruses | Eliminate pathogens | Sub-micron filtration |

| Color and Turbidity | Dyes, Suspended particles | Improve aesthetic quality | Nanofiltration with activated carbon pre-treatment |

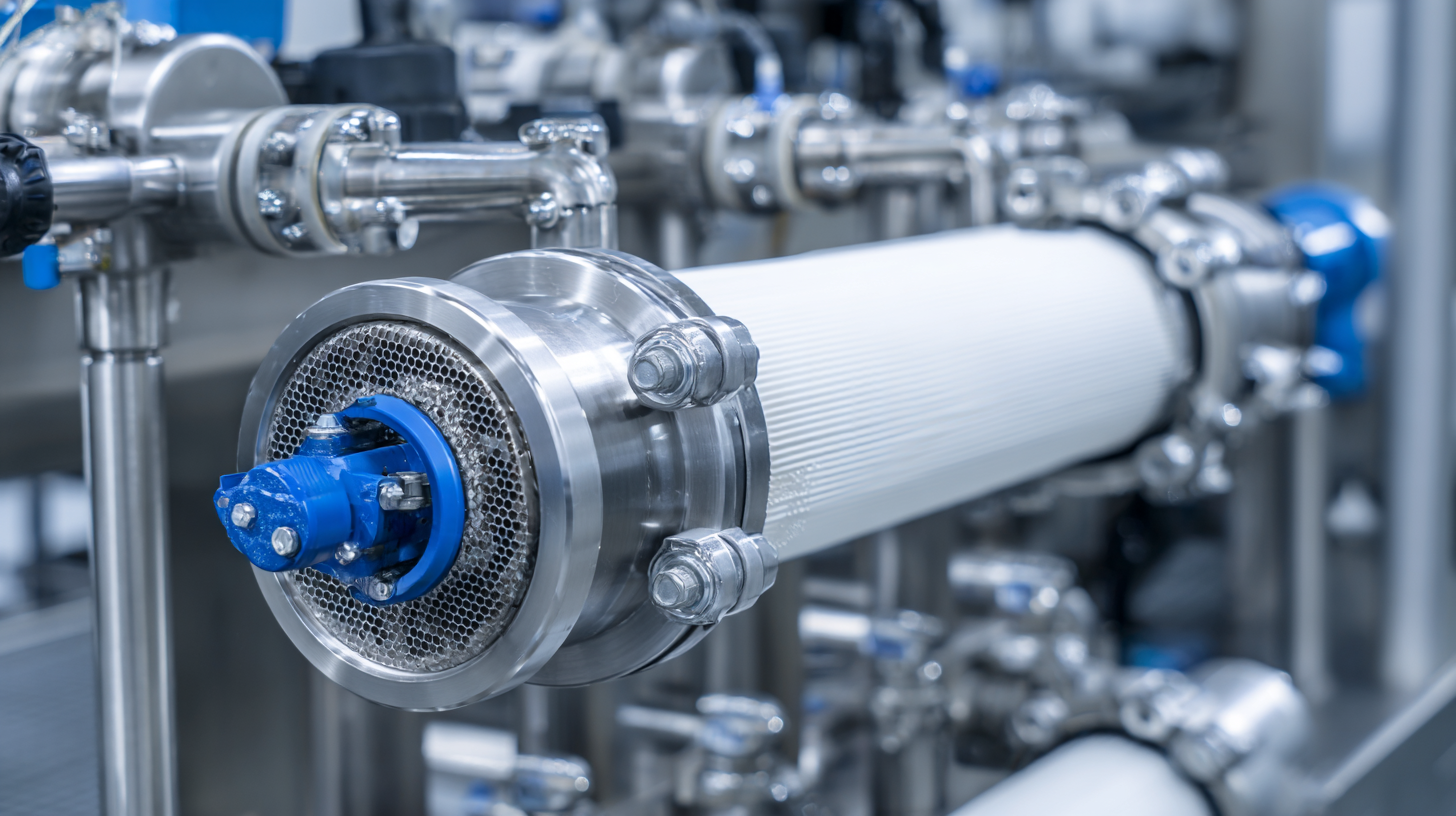

When selecting the appropriate nanofiltration (NF) membrane for specific water treatment needs, understanding the differences between polymeric and ceramic materials is crucial. Recent advancements in ceramic membrane technology have highlighted its effectiveness across various industries, including mining and petrochemicals, due to its superior chemical resistance and fouling properties. Ceramic membranes are gaining traction as they offer high stability, longer operational lifetimes, and enhanced throughput compared to their polymeric counterparts.

Studies indicate that ceramic membranes excel in wastewater treatment settings, making them an attractive option for industries facing stringent regulations and challenging water compositions. For instance, ceramic membranes have demonstrated remarkable performance in removing contaminants such as polyfluoroalkyl substances (PFAS) and have shown promising results in treating semiconductor wastewater through ammonium retention. With the global membranes market projected to grow significantly in the coming years, the shift towards sustainable solutions emphasizes the role of ceramic membranes in addressing both efficiency and environmental concerns, reinforcing their growing dominance in the filtration landscape.

When sizing your nanofiltration system, one of the primary considerations is the flow rate. This refers to the volume of water the system can treat within a given timeframe. It is essential to match the flow rate of the nanofiltration filter to your specific water treatment needs to ensure optimal performance and efficiency. For instance, a facility requiring high volumes of treated water during peak times may need a filter with a higher flow rate, while smaller operations might suffice with a lower capacity system. Calculating the daily water demand will help in selecting an appropriately sized filter that guarantees a consistent output.

In addition to flow rate, it’s crucial to consider the capacity of the nanofiltration unit. Capacity pertains to the total amount of water that can be treated over a given period without compromising filter integrity and performance. Factors such as the concentration of contaminants and the desired level of purification must be accounted for in capacity calculations. Regular monitoring and adjustments may be necessary to maintain optimal performance as these factors can shift over time. By carefully assessing both flow rate and capacity, you can tailor your nanofiltration system to meet specific treatment needs effectively.

When considering water treatment solutions, a cost-benefit analysis is essential to determine whether nanofiltration is the optimal choice compared to other technologies.

Nanofiltration (NF) offers a unique advantage in selectively removing contaminants while allowing beneficial minerals to pass through, making it a viable option for various applications. Its operational costs can be lower than reverse osmosis due to a reduced energy requirement and longer membrane lifespan, which can be significant in large-scale operations.

Nanofiltration (NF) offers a unique advantage in selectively removing contaminants while allowing beneficial minerals to pass through, making it a viable option for various applications. Its operational costs can be lower than reverse osmosis due to a reduced energy requirement and longer membrane lifespan, which can be significant in large-scale operations.

In comparison to conventional methods such as activated carbon filtration or microfiltration, nanofiltration combines efficiency with more extensive contaminant removal capabilities. While the initial investment may be higher than some traditional filters, the long-term savings on water quality and maintenance can justify the expenditure. Additionally, the lower disposal costs associated with NF membranes, compared to the sludge produced by other filtration methods, can further enhance its cost-effectiveness. Ultimately, understanding the specific needs of a water treatment project and evaluating these factors will guide the decision-making process in choosing the right nanofiltration filter.