Leave Your Message

Request a Quote

When selecting the appropriate water treatment solution, understanding the intricacies of a Nanofiltration System is vital for achieving optimal results. According to Dr. Jane Smith, a renowned expert in membrane filtration technology, "Choosing the right Nanofiltration System is not just about technology; it's about understanding your specific water quality needs and the desired outcomes.” This statement highlights the importance of a tailored approach when navigating the diverse options available in the market.

Nanofiltration Systems offer a unique balance of selectivity and permeability, making them ideal for various applications, from municipal water treatment to industrial processes. Their ability to effectively remove divalent ions and larger organic molecules while allowing monovalent salts to pass through provides a sophisticated solution for improving water quality. As such, potential users must evaluate their specific requirements, including feed water characteristics and intended end use, before making a decision.

In this discussion, we will delve into the critical factors to consider when choosing the right Nanofiltration System. By examining aspects such as operating conditions, system configuration, and maintenance requirements, we aim to equip stakeholders with the knowledge needed to make an informed decision that aligns with their water treatment goals.

Nanofiltration (NF) has become increasingly critical in water treatment applications, particularly due to its ability to effectively remove organic compounds and divalent ions while allowing monovalent ions to pass through. This selective permeability makes NF systems ideal for applications such as softening hard water and removing color or organic contaminants from various water sources. According to a report by IDTechEx, the nanofiltration market is projected to grow substantially, driven by an increasing demand for clean and safe drinking water, which highlights the significant role NF plays in addressing global water scarcity.

Moreover, the versatility of nanofiltration systems allows them to be utilized across a range of industries, from municipal water treatment to food and beverages, and even pharmaceuticals. A study from the American Water Works Association indicates that the integration of NF in treatment processes can lead to a reduction of up to 80% in chemical usage for softening applications. This not only enhances sustainability but also reduces operational costs significantly. The importance of nanofiltration in maintaining water quality cannot be overstated, as it helps meet regulatory requirements while addressing the growing concerns over water contamination.

This chart illustrates the efficiency of various nanofiltration systems in removing specific contaminants commonly found in water treatment applications. The systems are compared based on their removal rates for common contaminants like hardness, chloride, and sulfates.

When selecting a nanofiltration system for your water treatment needs, it's crucial to consider several key factors that influence both efficacy and suitability. First and foremost, evaluate the specific contaminants present in your water supply. Nanofiltration is particularly effective against divalent ions and larger organic molecules, but understanding the profile of pollutants will help determine whether this filtration method can meet your requirements. Conducting a comprehensive water quality analysis provides insights into the parameters you need to address.

Another essential factor is the system's membrane characteristics. The choice of membrane material, pore size, and flux rate can significantly affect the performance and longevity of the nanofiltration system. When assessing membranes, take into account their resistance to fouling and scaling, as well as their chemical compatibility with the substances in your water. Furthermore, consider the operational parameters, such as pressure and temperature, which can impact the efficiency of filtration. Ensuring that the selected system aligns with your operational conditions and maintenance capabilities will contribute to the long-term viability of your water treatment solution.

Nanofiltration (NF) technology has gained attention for its ability to effectively remove divalent ions and organic compounds while allowing monovalent ions to pass through. This unique selectivity positions NF as a versatile option in the membrane filtration landscape, especially when compared to other technologies such as reverse osmosis (RO) and ultrafiltration (UF). While RO provides a higher rejection rate, making it suitable for applications requiring the removal of all dissolved solids, it also requires more energy and results in higher operational costs. In contrast, NF operates at lower pressure and energy levels, making it an attractive compromise for treating water that contains both organic matter and hardness while still allowing essential minerals.

When evaluating these membrane technologies, one must also consider their specific applications and the types of contaminants being targeted. For instance, UF is primarily effective in removing larger particles and suspended solids but offers limited removal of dissolved salts. This makes it less suitable for applications requiring thorough demineralization. On the other hand, NF serves as a bridge between UF and RO, providing a balance of permeate quality and operational efficiency. The choice between these technologies ultimately hinges on the specific water treatment goals, whether those are to reduce hardness, eliminate specific contaminants, or achieve a balance of both.

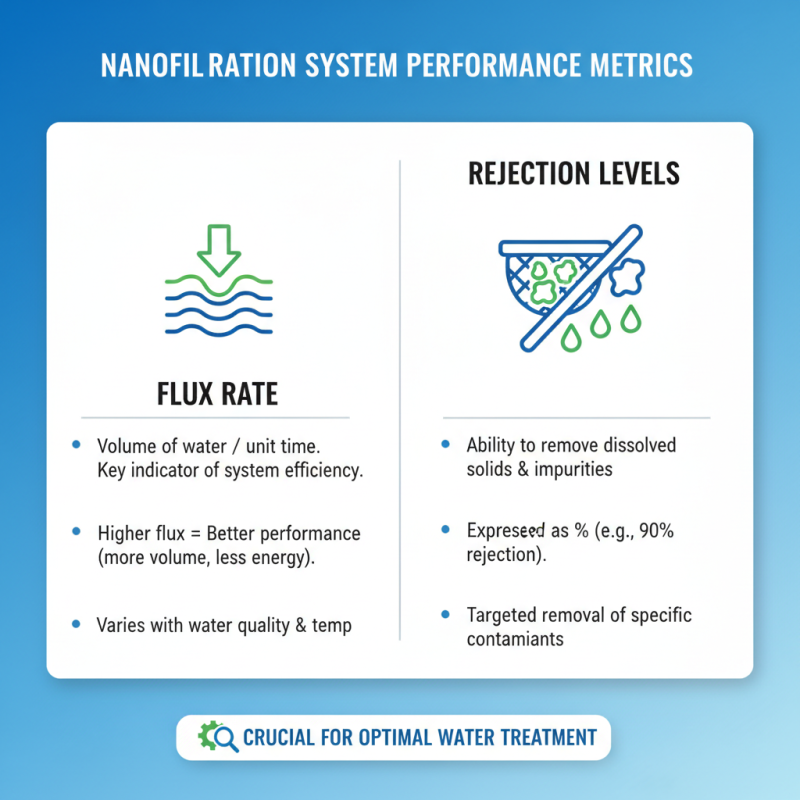

When selecting a nanofiltration system for water treatment, understanding performance metrics such as flux rates and rejection levels is crucial. Flux rate, defined as the volume of water that passes through a membrane per unit time, is a key indicator of a system’s efficiency. A higher flux rate typically signifies better performance, allowing for greater volume processing without a significant increase in energy consumption. It's essential to consider the specific water quality and treatment goals because optimal flux rates can vary widely based on factors such as feed water characteristics and temperature.

Rejection levels, on the other hand, determine the effectiveness of a nanofiltration system in removing contaminants. This metric refers to the percentage of a specific substance that is filtered out from the water. For example, if a system has a rejection level of 90% for a particular ion, it means that 90% of that ion is removed from the water during treatment. High rejection levels are vital for scenarios needing stringent water quality, such as in industrial applications or advanced municipal treatment facilities. Balancing flux rates and rejection levels is essential; a system with high flux may sacrifice some rejection efficiency, making it vital for users to assess their specific needs to ensure the chosen system meets both performance and quality requirements.

When evaluating the cost-benefit of nanofiltration systems in industrial applications, it’s crucial to assess both the initial investment and the long-term operational expenses. While the upfront cost of these systems can be significant, they often lead to substantial savings in water treatment processes. For industries requiring high-quality effluent or specific contaminant removal, the efficiency of nanofiltration can offset high energy or maintenance costs by reducing the need for additional processing steps or chemical treatments.

**Tips**: Always conduct a comprehensive needs assessment to identify the critical parameters for your water treatment. It’s beneficial to understand the specific contaminants in your water source and how a nanofiltration system can address them effectively. Furthermore, consider the potential for system scalability, as future growth may necessitate adjustments or expansions.

Another essential consideration involves the operational efficiency and lifespan of the membranes used in nanofiltration systems. Regular maintenance and monitoring can enhance performance and reduce replacement costs. By establishing a routine maintenance schedule, industries can avoid costly downtime and ensure consistent water quality. Evaluating the total lifecycle cost, including maintenance, energy, and potential re-investments, will provide a clearer picture of the financial implications involved in selecting the right nanofiltration system for your specific needs.

| System Type | Initial Cost (USD) | Operating Cost (USD/Year) | Maintenance Cost (USD/Year) | Expected Lifetime (Years) | Water Recovery Rate (%) | Ideal Application |

|---|---|---|---|---|---|---|

| Modular Nanofiltration System | 15,000 | 2,500 | 1,200 | 10 | 85 | Food and Beverage Industry |

| Compact Nanofiltration Unit | 20,000 | 3,000 | 1,500 | 8 | 80 | Textile Industry |

| High-Flux Nanofiltration System | 30,000 | 4,000 | 2,000 | 15 | 90 | Pharmaceutical Industry |

| Skid-Mounted Nanofiltration System | 25,000 | 3,500 | 1,800 | 12 | 95 | Municipal Water Treatment |