Leave Your Message

Request a Quote

In today's fast-evolving filtration industry, selecting the right Membrane Filter is crucial for achieving optimal results in various applications, from pharmaceuticals to water treatment. According to a report by MarketsandMarkets, the global membrane filtration market is projected to reach USD 26.5 billion by 2026, growing at a compound annual growth rate (CAGR) of 10.4% from 2021 to 2026. This growth can be attributed to the increasing demand for clean water and the rising need for efficient separation processes.

With numerous options available, choosing the best Membrane Filter tailored to your specific needs can enhance operational efficiency, reduce costs, and ensure compliance with regulatory standards. This blog explores seven compelling reasons to guide your decision-making process when selecting the optimal Membrane Filter for your applications.

Membrane filters play a crucial role in various industrial applications, particularly in sectors such as pharmaceuticals, food and beverage, and water treatment. According to a report by MarketsandMarkets, the global membrane filtration market is projected to reach $39.1 billion by 2025, driven by the increasing demand for high-quality filtration solutions. The importance of quality in membrane filters cannot be overstated; they directly influence product purity, process efficiency, and compliance with strict regulatory standards.

High-quality membrane filters are engineered to ensure optimal performance. For instance, effective membrane filters can remove up to 99% of contaminants, including bacteria and viruses, which is critical in pharmaceutical manufacturing, where even trace amounts of impurities can affect product safety. Additionally, a survey by the American Water Works Association found that organizations utilizing superior filtration technology experienced a 30% increase in operational efficiency due to reduced downtime and lower maintenance costs. These statistics highlight the vital role that quality membrane filters play in safeguarding product integrity and enhancing industrial processes.

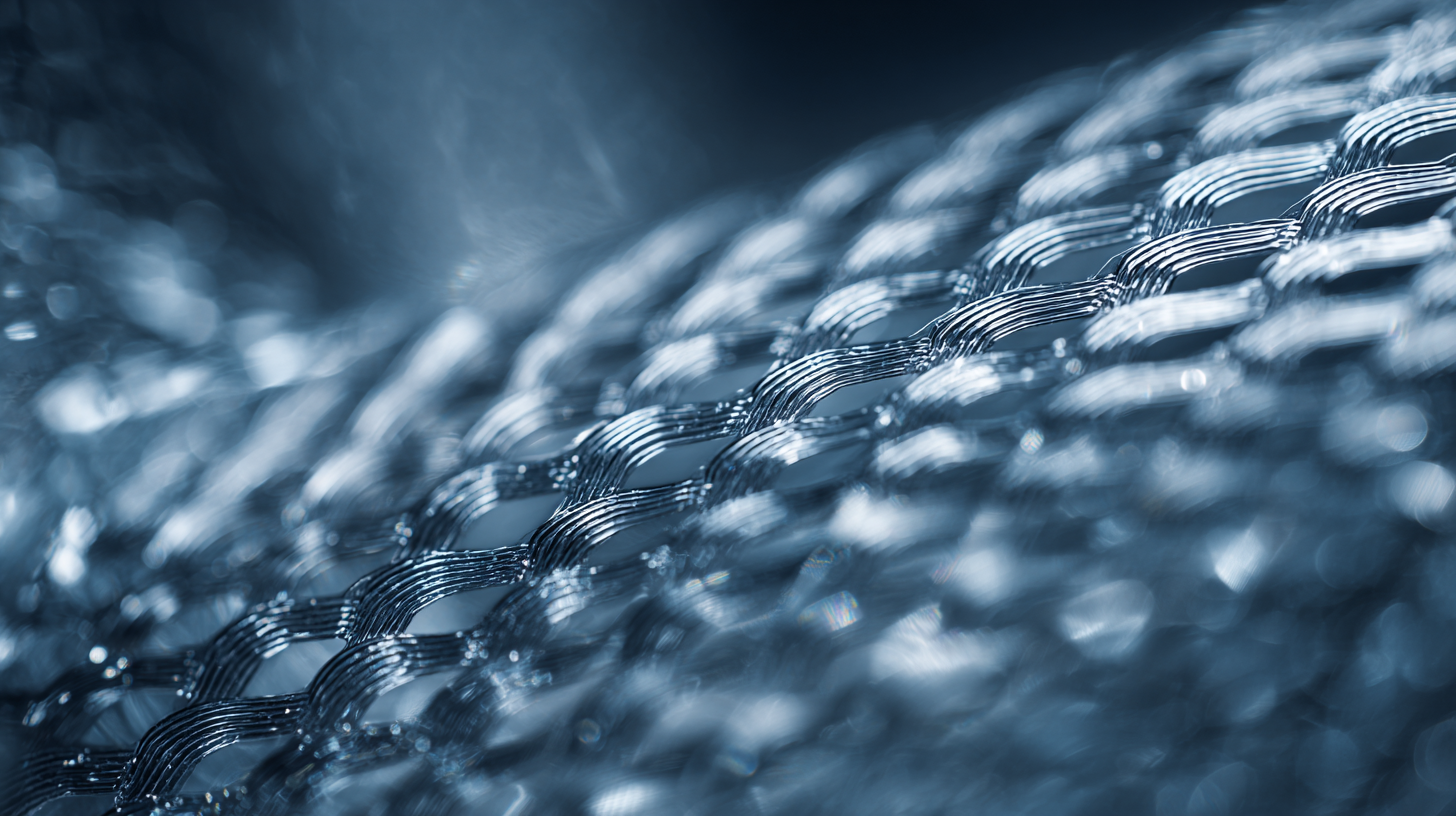

When selecting the best membrane filter for your specific needs, understanding the different types available is essential. Membrane filters are categorized based on their pore size, material composition, and application. For instance, polycarbonate, cellulose nitrate, and polyethersulfone membranes exhibit varying performance characteristics for microbial analysis in clean waters. A recent study highlighted that while polycarbonate membranes offer high filtration efficiency, cellulose nitrate is noted for its effectiveness in retaining various microorganisms, crucial for sterile filtration processes.

In environmental applications, membrane technology plays a pivotal role in microplastic analysis and wastewater treatment. Research indicates that direct membrane filtration can significantly enhance water quality and facilitate resource recovery, addressing both contamination risks and conservation efforts. Additionally, advancements in high-pressure membrane systems, such as reverse osmosis, have demonstrated remarkable capabilities in purifying wastewater and uncovering microbial biodiversity. Such innovations are vital, as they not only improve operational efficiency but also support sustainable practices in managing water resources. Therefore, selecting the right membrane filter type can have profound implications for both environmental sustainability and industrial applications.

When selecting the best membrane filter for your needs, understanding key features is crucial. One of the primary aspects to consider is the pore size of the membrane. Pore size directly influences the type of contaminants that can be removed from the fluid being filtered, making it essential to match the membrane’s specifications with your filtration requirements. For instance, if you are aiming to remove bacteria, a membrane with a pore size of 0.2 microns is typically recommended for effective results.

Another vital feature to look for is the material composition of the membrane. Different materials offer various benefits, such as chemical resistance, thermal stability, and compatibility with specific applications. For example, polyethersulfone (PES) membranes are renowned for their robust performance in harsh chemical environments while maintaining a high flow rate. Additionally, consider the membrane's durability and ease of cleaning, as these factors can significantly impact operational efficiency and long-term costs in industrial settings. By focusing on these key features, you can ensure that you choose a membrane filter that meets your specific needs and provides reliable performance.

| Feature | Importance | Typical Applications | Material | Pore Size (µm) |

|---|---|---|---|---|

| Separation Efficiency | Critical for purifying fluids | Water treatment, pharmaceuticals | Polyethersulfone (PES) | 0.2 |

| Chemical Compatibility | Ensures longevity and performance | Food and beverage, biotechnology | Polytetrafluoroethylene (PTFE) | 0.45 |

| Flow Rate | Efficiency in processing volumes | Industrial filtration, wastewater | Polyvinylidene Fluoride (PVDF) | 0.1 |

| Temperature Resistance | Essential for high-temperature processes | Chemical processing, sterilization | Polyamide (Nylon) | 0.45 |

| Regeneration Capability | Sustainability and cost-effectiveness | Wastewater recycling | Ceramic | 0.05 |

| Surface Area | Increases filtration efficiency | Laboratory application | Glass fiber | 0.7 |

| Cost-Effectiveness | Balanced upfront and lifecycle costs | General filtration | Cellulose acetate | 0.2 |

Selecting the right membrane filter is crucial for optimizing the efficiency of your entire system. The type of membrane you choose directly affects not just the filtration performance but also energy consumption and operational costs. For example, membranes with higher selectivity can reduce the need for additional post-filtration processes, thereby streamlining the entire system. When membranes efficiently separate desired particles from liquids, it minimizes downtime and extends the life of the system components.

Tips: Always consider the compatibility of the membrane material with the fluids being processed. This compatibility can prevent potential degradation and ensure better filtration outcomes. Additionally, conducting a pilot test can provide valuable insights into how well a specific membrane performs in your application, helping you make a more informed decision.

Moreover, selecting the optimal pore size is vital. A membrane with pores that are too large may not effectively filter out unwanted particles, while one that is excessively small could increase pressure drops and energy consumption. Maintaining a balance between filtration efficiency and system performance is key, ensuring that you achieve the desired outcomes without incurring unnecessary costs.

Tips: Regularly monitor and maintain the membrane system to detect any changes in performance early on. This proactive approach can extend the longevity of the membranes and ensure that your system continues to operate efficiently.

As the global pharmaceutical membrane filtration market is expected to reach USD 27,620 million by 2033, with a remarkable compound annual growth rate (CAGR) of 13.4%, the importance of advanced membrane filter technology cannot be overstated. A key player in this progression is the role of Chinese manufacturers, who have significantly contributed to enhancing membrane filter efficiency and affordability. These companies not only innovate but also cater to the diverse needs of global clientele, ensuring that complex requirements for filtration in pharmaceuticals are met with precision.

Chinese manufacturers are leveraging advanced technologies and research to produce membrane filters that meet stringent industry standards. Their ability to integrate cutting-edge materials and manufacturing processes has allowed them to create filters that provide better performance and longer lifespan at competitive prices. This positions them as essential contributors to the ongoing evolution of membrane filtration, ultimately benefiting pharmaceutical companies looking to enhance their production processes and ensure the highest quality of their products.