Leave Your Message

Request a Quote

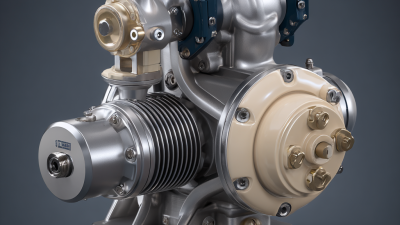

In the world of fluid handling solutions, diaphragm pumps stand out due to their versatility and efficiency. As industries increasingly seek reliable and effective ways to transfer various substances, understanding the benefits of diaphragm pumps is crucial. According to Mark Thompson, a renowned expert in the diaphragm pump sector, "The unique design of diaphragm pumps not only enhances their performance but also extends their lifespan, making them an invaluable asset across multiple applications." This quote encapsulates the essence of why diaphragm pumps have become a go-to solution for many businesses.

Diaphragm pumps operate on a simple yet effective mechanism, which allows them to handle a wide range of fluids, including corrosive substances, slurries, and viscous materials. Their ability to provide precise flow control and run dry without damage makes them particularly valuable in sectors such as chemical processing, wastewater management, and food and beverage manufacturing. As we delve into the top 10 benefits of diaphragm pumps, it becomes evident that these pumps are not merely functional devices, but rather key players in optimizing industrial performance and increasing operational efficiency. Understanding these advantages can help businesses make informed decisions when selecting equipment for their fluid transfer needs.

Diaphragm pumps have earned a reputation for their adaptability across various industrial applications, making them indispensable in today’s manufacturing landscape. Their unique design allows for the handling of a wide array of fluids, including corrosive chemicals, viscous materials, and even slurries, highlighting their versatility. According to a recent market analysis by Grand View Research, the global diaphragm pump market is projected to reach $6.8 billion by 2025, reflecting an annual growth rate of 5.8%. This growth is driven by the increasing demand for efficient and reliable fluid transfer solutions in industries such as pharmaceuticals, food processing, and wastewater management.

One significant advantage of diaphragm pumps lies in their ability to operate dry without damage, which is particularly beneficial in applications where fluid availability may be inconsistent. Additionally, they maintain a higher level of efficiency compared to traditional pump types, which can lead to substantial cost savings.

Tip: To ensure optimal performance, always select a diaphragm pump that matches the viscosity and chemical compatibility of the fluid being pumped. Regular maintenance and inspections can also prevent potential downtime and enhance longevity. Overall, the continuous advancement in diaphragm pump technology promises even greater versatility and efficiency for a wide range of industrial applications.

Diaphragm pumps have gained popularity across various industries due to their remarkable advantages, particularly in enhancing fluid transfer efficiency. One of the primary benefits is their ability to handle a wide range of fluids, including viscous, abrasive, and shear-sensitive materials. With their unique design that utilizes a flexible diaphragm to create a pumping action, these pumps minimize the risk of contamination and ensure that fluids maintain their integrity during transfer. As a result, industries such as pharmaceuticals, food and beverage, and chemicals often favor diaphragm pumps for critical applications.

Another significant advantage of diaphragm pumps lies in their ability to operate dry without damage, allowing for greater flexibility in various operational conditions. This feature is particularly beneficial in environments where fluid supply may be inconsistent. Moreover, the self-priming capability of diaphragm pumps means they can operate efficiently in less than ideal conditions, reducing downtime and maintenance costs. Overall, these characteristics make diaphragm pumps an optimal choice for businesses seeking reliable and efficient fluid transfer solutions, driving improved operational performance and cost-effectiveness.

Diaphragm pump technology has emerged as a significant contributor to sustainability in various industries. With the growing awareness of environmental concerns, diaphragm pumps are designed to minimize resource consumption and reduce waste. According to a report by the Global Pump Industry Association, diaphragm pumps can achieve energy savings of up to 30% compared to traditional pumping technologies. This efficiency not only lowers operational costs for companies but also supports their sustainability goals by decreasing their carbon footprint.

Furthermore, diaphragm pumps excel in handling a wide range of fluids, including corrosives and abrasive materials, without the risk of leakage common in other pump types. This feature significantly reduces the possibility of environmental contamination, supporting eco-friendly practices. A study published in the Journal of Cleaner Production highlighted that implementing diaphragm pumps in industrial settings could lead to a 40% reduction in chemical spillage incidents over conventional pumping systems. This underscores the vital role diaphragm pumps play in promoting safety and sustainability in operational processes across diverse industries.

| Benefit | Description | Impact on Sustainability | Industry Insights |

|---|---|---|---|

| High Efficiency | Diaphragm pumps can achieve high volumetric efficiency. | Reduced energy consumption leads to lower carbon footprint. | Industries are shifting towards energy-efficient technologies. |

| Leak-Free Operation | Preventing leaks minimizes product loss. | Supports eco-friendly practices by reducing waste. | Regulatory standards enforce more stringent controls on leaks. |

| Versatility | Handles a variety of fluids, including viscous and abrasive substances. | Enables efficient recycling and reuse of materials. | Increased demand for multifunctional pumping solutions. |

| Low Maintenance | Fewer moving parts lead to reduced maintenance needs. | Less frequent repairs result in lower resource consumption. | Advancements in design are promoting longer service life. |

| Self-Priming | Can operate in various orientations without priming issues. | Less energy waste during start-up phases. | Enhances operational flexibility in diverse environments. |

| Gentle Handling | Ideal for shear-sensitive fluids. | Maintains product integrity, reducing wastage. | Growing interest in low-shear processes in food and pharmaceuticals. |

| Durability | Constructed from robust materials for long-lasting performance. | Contributes to lower replacement rates and waste generation. | Manufacturers focus on durable designs to meet industrial demands. |

| Safety Features | Designed with built-in safety features to minimize risks. | Reduces the likelihood of hazardous leaks, promoting workplace safety. | Health and safety regulations are driving improvements in pump design. |

| Cost-Effectiveness | Lower operational costs compared to other pump types. | Promotes sustainable practices by minimizing costs associated with waste. | Businesses prioritize cost-efficient technologies. |

| Eco-Friendly Materials | Options available with biodegradable and recyclable materials. | Encourages sustainable production practices. | Increasing market demand for environmentally friendly products. |

When comparing diaphragm pumps to traditional pump systems, several distinct advantages emerge that enhance performance and efficiency across various industries. Diaphragm pumps operate through a unique mechanism that utilizes a flexible diaphragm to create a vacuum, allowing for precise control over fluid flow. This design minimizes the risk of leaks and contamination, making diaphragm pumps particularly suitable for handling corrosive or abrasive materials. In contrast, traditional pumps often rely on mechanical seals that can wear down, leading to potential failures and maintenance issues.

Additionally, diaphragm pumps offer superior adaptability to varying flow rates and pressures, enhancing their versatility in applications ranging from wastewater treatment to pharmaceuticals. While traditional pump systems may struggle with fluctuating demands, diaphragm pumps can efficiently manage diverse operational conditions, reducing energy consumption and extending equipment life. The ability to run dry without damage, a feature not always found in conventional pumps, further underscores the reliability of diaphragm technology in critical processes. This comparative advantage positions diaphragm pumps as a preferred choice for industries prioritizing efficiency and safety.

The future of diaphragm pump design is poised for transformative innovations that promise significant enhancements in performance across various industries. One of the key trends is the integration of smart technologies, such as IoT sensors, which provide real-time monitoring and diagnostics. This advancement allows for predictive maintenance, minimizing downtime and maximizing efficiency in operations. By utilizing data analytics, operators can optimize pump performance based on usage patterns and environmental conditions, leading to cost savings and improved reliability.

Additionally, advancements in materials science are contributing to the evolution of diaphragm pumps. The development of more durable and chemical-resistant materials enhances the pumps' longevity and performance in harsh environments. Innovations like high-efficiency diaphragms are also designed to minimize energy consumption while maximizing flow rates. As manufacturers continue to invest in research and development, the focus will be on creating diaphragm pumps that are not only efficient and effective but also environmentally friendly, catering to the growing demand for sustainable solutions in industrial applications.