Leave Your Message

Request a Quote

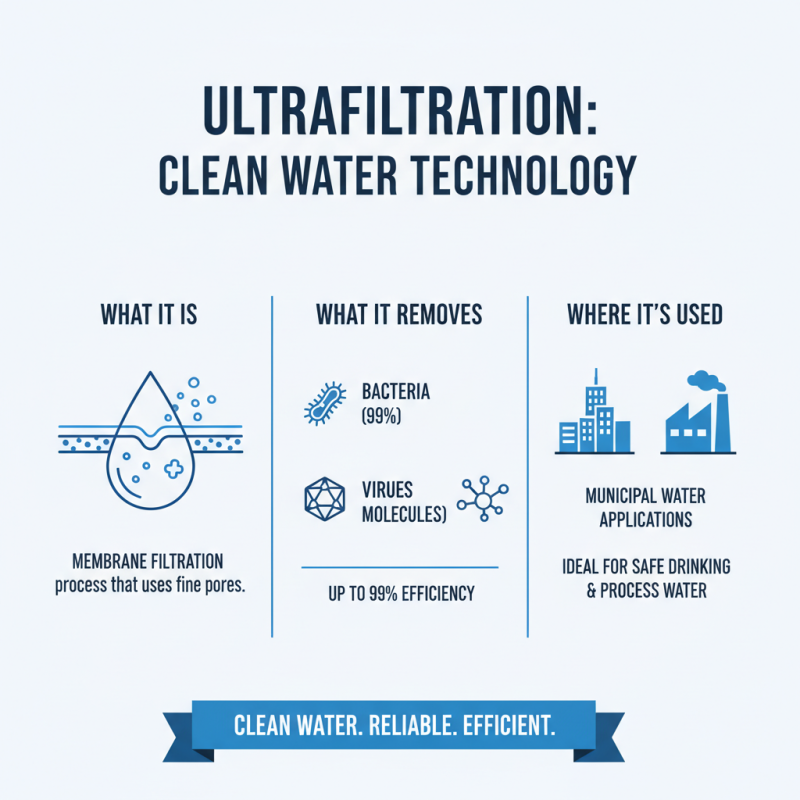

Ultrafiltration is a powerful water purification method. It removes contaminants effectively, ensuring safe drinking water. The process uses membranes to separate particles from water. This technology can filter bacteria, viruses, and larger sediments.

While ultrafiltration is effective, several tips can enhance its efficiency. For instance, maintaining proper pressure is crucial. Low pressure can reduce the system’s performance. On the other hand, excessive pressure may damage the membranes. Regular cleaning is essential, too. Accumulated dirt can hinder flow and efficacy.

It’s also important to monitor water quality consistently. You may find that your ultrafiltration system needs adjustments. Understanding your water source will allow for better treatment choices. Overall, ultrafiltration offers significant benefits, but it requires careful attention and management.

Ultrafiltration is a crucial process in water purification. It utilizes a membrane that allows water and small molecules to pass while blocking larger particles. Typically, ultrafiltration membranes have a pore size of about 0.01 to 0.1 microns. This capability effectively removes bacteria, viruses, and organic compounds. According to a recent industry report, ultrafiltration can reduce contaminants by up to 99%, making it a reliable option for clean water.

To enhance ultrafiltration efficiency, regular maintenance of the system is essential. Clogged membranes can lead to decreased performance. It’s vital to monitor pressure and flow rates frequently. Consider backwashing the membranes periodically. Additionally, pretreatment of water can reduce fouling. This step can be vital to prolonging the lifespan of your ultrafiltration system.

When implementing ultrafiltration, be aware of potential limitations. Not all contaminants are removed effectively, particularly some dissolved salts. A study highlighted that ultrafiltration works best in combination with other purification methods. Finding the right balance is key. Achieving the highest water quality can take time and adjustment. Recognizing these aspects can lead to better water purification outcomes.

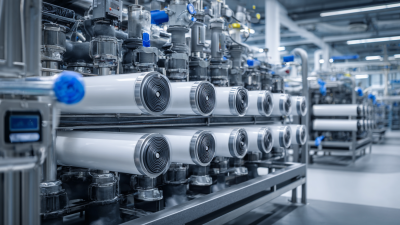

Ultrafiltration systems are pivotal for water purification. They use membranes to remove particles and contaminants. These membranes have specific pore sizes, typically less than 0.1 microns. This can effectively filter out bacteria, viruses, and even some larger organic molecules. Key components include the membrane module, pressure vessels, and pre-treatment systems. Each plays a critical role in ensuring efficient operation.

When setting up an ultrafiltration system, consider these tips. Regularly check the membrane condition. Membranes can degrade, leading to reduced performance. Keep an eye on pressure levels. Fluctuations can indicate fouling or scaling issues. Pre-treatment is crucial. Use sediment filters to extend membrane life. Failing to pre-treat water can cause early membrane failure.

Maintenance is a challenge. Cleaning membranes requires specific solutions. Failure to follow protocols can harm membrane integrity. It's essential to evaluate the entire system continually. Are your pre-treatment methods effective? Regular assessments can improve water quality. Maintain diligence in monitoring and adapting your ultrafiltration system for optimal results.

When selecting an ultrafiltration membrane, several factors matter. Consider the pore size. It should match the particles you wish to filter. Smaller pores can trap more contaminants. However, they can also reduce flow rates. Finding the right balance is key.

Think about the membrane material. Polyethersulfone (PES) is a common choice. It offers good chemical resistance. Yet, it may not be suitable for all applications. Evaluate your specific needs. Failure to do so can lead to poor performance.

Don’t forget about maintenance. Some membranes require more care than others. Regular cleaning can extend their lifespan. Neglect can result in fouling, which reduces efficiency. Be prepared to invest time in upkeep. An ignored membrane can cause bigger issues down the line.

| Parameter | Description | Considerations |

|---|---|---|

| Pore Size | Generally range from 0.1 nm to 0.01 µm, effectively removing bacteria and viruses. | Choose based on the contaminants present in the water source. |

| Material | Common materials include polymeric membranes and ceramic membranes. | Consider durability, chemical resistance, and cost. |

| Flux Rate | The rate at which water can pass through the membrane, typically measured in liters per square meter per hour (LMH). | Higher flux rates may lead to faster filtration but could affect membrane lifespan. |

| Cleaning Protocol | Methods to maintain membrane performance and longevity, including chemical cleaning and backwashing. | Frequency and type of cleaning should align with the feed water quality. |

| Temperature Range | Operating temperatures can affect permeability and fouling. | Select membranes that can endure the temperature of the feed water. |

| Application | Used in various sectors such as drinking water purification, wastewater treatment, and food processing. | Identify the precise application to ensure the required specifications are met. |

Maintaining an ultrafiltration system is crucial for optimal water purification. Regular maintenance ensures longevity and effectiveness. Filters should be checked frequently. Clogs can occur. This can lead to reduced flow rates and purification efficiency. Always keep an eye on pressure gauges. If they show unusual readings, it might be time for a filter change.

Cleaning the membranes is another essential practice. Over time, contaminants build up on the surface. This can hinder performance. Use appropriate cleaning solutions to restore function. Rinse thoroughly after cleaning. This prevents chemical residues from affecting water quality. Remember to follow guidelines for cleaning intervals. It’s easy to forget this step in a busy schedule.

Considerations about water quality are important too. Different water sources may require customized approaches. Pay attention to variations in turbidity. High levels can overwhelm the filtration process. During heavy rainfall, it’s wise to test the water quality. Not all systems respond the same way to extreme conditions. Stay observant and adjust as needed. Water purification can be complex, and one size does not fit all.

Ultrafiltration (UF) is a promising technology for water treatment, effectively removing particles and contaminants. It can filter out bacteria, viruses, and organic molecules. Reports indicate that UF membranes can achieve a removal efficiency of up to 99%. This makes it ideal for municipal water supplies and industrial applications. Many facilities use ultrafiltration to ensure clean water.

Common applications for ultrafiltration include wastewater treatment and food processing. In wastewater treatment, UF membranes provide a barrier against solid matter. This leads to cleaner effluent and less environmental impact. In the food industry, ultrafiltration helps concentrate liquids and clarify beverages, leading to higher quality products. A study found that using UF can reduce processing costs by 30%.

Here are some tips for effective ultrafiltration. Regular maintenance of membranes enhances their lifespan. Monitor pressure drops to prevent fouling. An automatic cleaning system may be necessary for consistent performance. Be prepared for occasional system checks. Understanding these aspects can lead to better water purification outcomes.