Leave Your Message

Request a Quote

In the dynamic world of industrial equipment, selecting the right Pump Diaphragm is crucial for ensuring optimal performance and efficiency. A recent report by Global Market Insights indicates that the diaphragm pump market is poised to exceed $5 billion by 2026, underscoring the growing demand for reliable pumping solutions across various sectors, including chemicals, pharmaceuticals, and wastewater management. As industries increasingly prioritize sustainability and cost-effectiveness, choosing the right diaphragm can significantly impact operational reliability and maintenance costs. This article provides essential tips for identifying high-quality suppliers, ensuring that you make informed choices tailored to your specific needs.

By adhering to a comprehensive checklist, businesses can leverage the latest innovations in pump diaphragm technology and enhance their overall productivity.

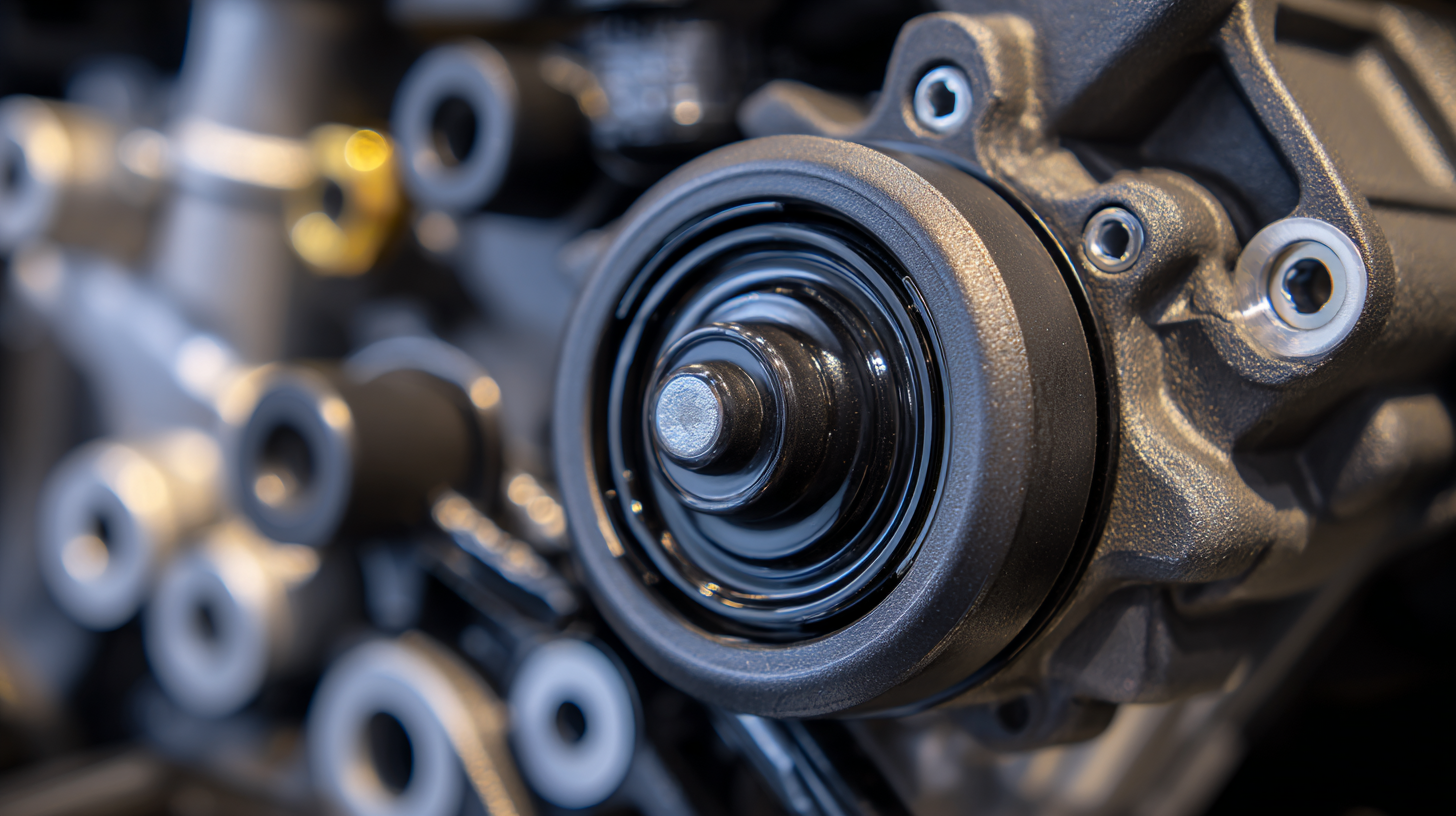

When selecting the best pump diaphragm for your specific applications, understanding the different types available and their respective uses is crucial. Pump diaphragms are primarily categorized into three types: fabric-reinforced, solid elastomer, and thermoplastic. Each has unique properties that cater to varying demands—from chemical resistance to durability under high pressure. For instance, a report by the Fluid Handling Institute noted that nearly 60% of industrial pumps utilize elastomeric diaphragms due to their flexibility and resistance to extreme conditions.

Tip 1: Assess your application’s requirements. Consider factors such as temperature, pressure, and the type of fluid being pumped. For example, if you're working with corrosive substances, a thermoplastic diaphragm might be more suitable.

Additionally, understanding the operating environment can help narrow your options. In high-cycle applications, a fabric-reinforced diaphragm will often outperform others due to its resilience. The 2022 Pump Industry Report highlighted that proper diaphragm selection can reduce maintenance costs by up to 25%, showcasing the importance of making an informed choice.

Tip 2: Review manufacturer specifications. Detailed performance data will help you compare diaphragms on crucial factors like flow rate, efficiency, and lifespan. By prioritizing quality and compatibility, you can ensure optimal system performance and longevity.

When selecting a pump diaphragm, several key factors can significantly influence your choice. First and foremost, consider the material of the diaphragm. According to a recent industry report by the Fluid Power Journal, materials such as EPDM and PTFE are widely recognized for their durability and resistance to chemicals. Selecting the right material not only affects the performance of your pump but also its longevity, ultimately impacting maintenance costs.

Another critical aspect is the diaphragm design. A report from the International Journal of Fluid Mechanics highlights that a well-engineered diaphragm can enhance the efficiency of fluid transfer by 15% to 20%. When evaluating designs, look for features that reduce wear and improve flow rates.

Additionally, it's essential to assess compatibility with the fluids being pumped. Compatibility issues can lead to premature failure, costing companies thousands in replacement and downtime. Always consult manufacturer guidelines and consider conducting tests when necessary. By prioritizing these factors, you'll be better equipped to choose the pump diaphragm that meets your specific needs and operational requirements.

| Factor | Description | Considerations |

|---|---|---|

| Material | The type of material used for the diaphragm affects chemical resistance and durability. | Select according to the fluid being pumped. |

| Size | Diaphragm size must match the pump's specifications for optimal performance. | Consult the pump’s manual for correct sizing. |

| Operating Pressure | Diaphragms are rated for specific pressure ranges. | Ensure the diaphragm can handle your system's pressure needs. |

| Temperature Resistance | Certain materials only perform well under specific temperature ranges. | Check operational temperature against diaphragm specs. |

| Flexibility | Some applications require more flexible diaphragms for better performance. | Evaluate application needs for flexibility. |

| Compression Strength | The ability of the diaphragm to withstand compression loads. | Check the compression requirements of your application. |

| Cost | Balancing between quality and budget. | Consider total lifecycle cost, not just upfront price. |

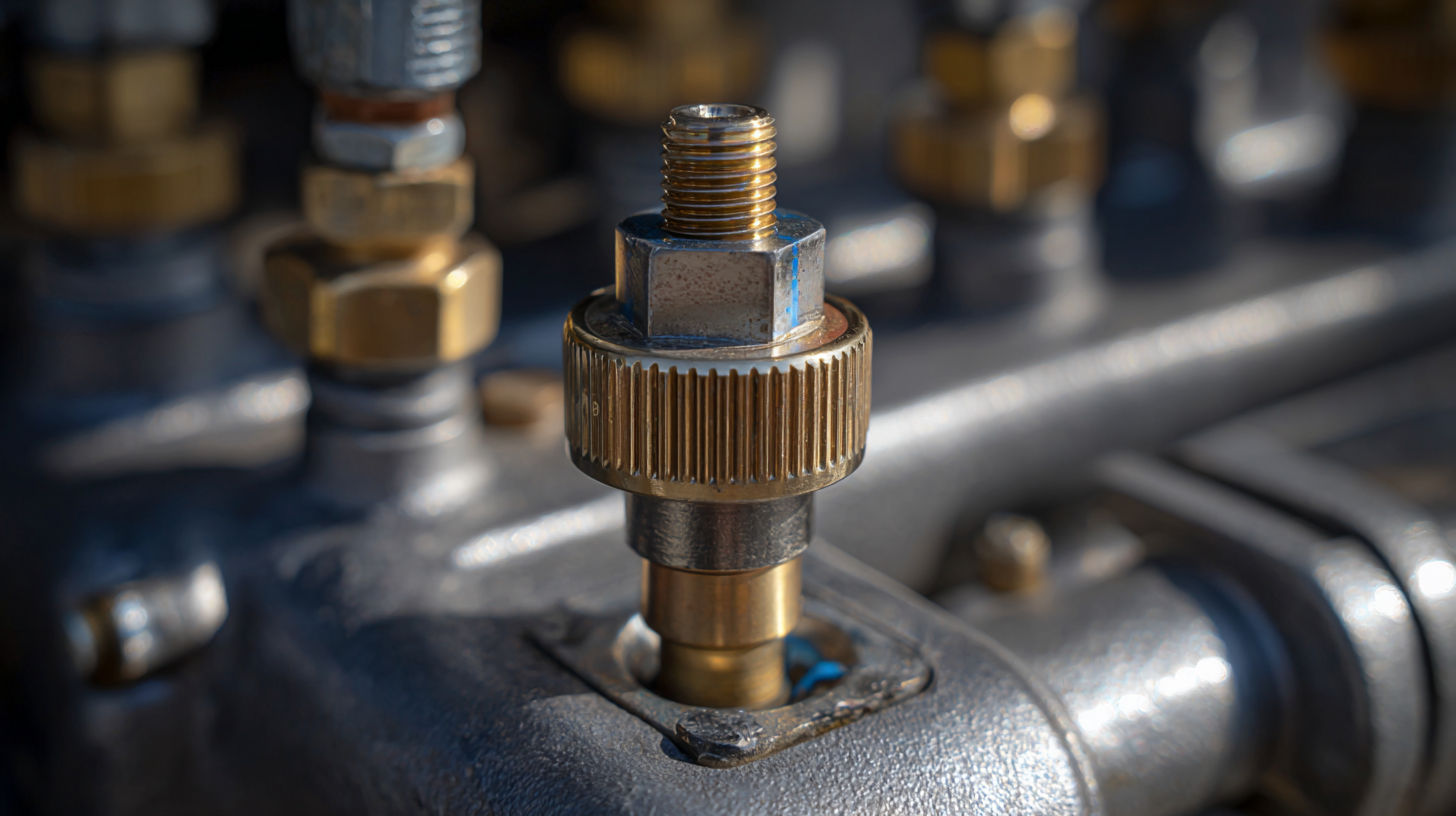

When selecting a suitable pump diaphragm, one of the most critical factors to consider is material compatibility. The diaphragm is often the first line of defense against leakage and contamination in various applications, and the appropriate material ensures optimal performance and longevity. According to industry studies, over 30% of diaphragm failures are attributed to incompatibility with the process media, highlighting the need for thorough evaluation of material properties such as chemical resistance, temperature tolerance, and mechanical strength.

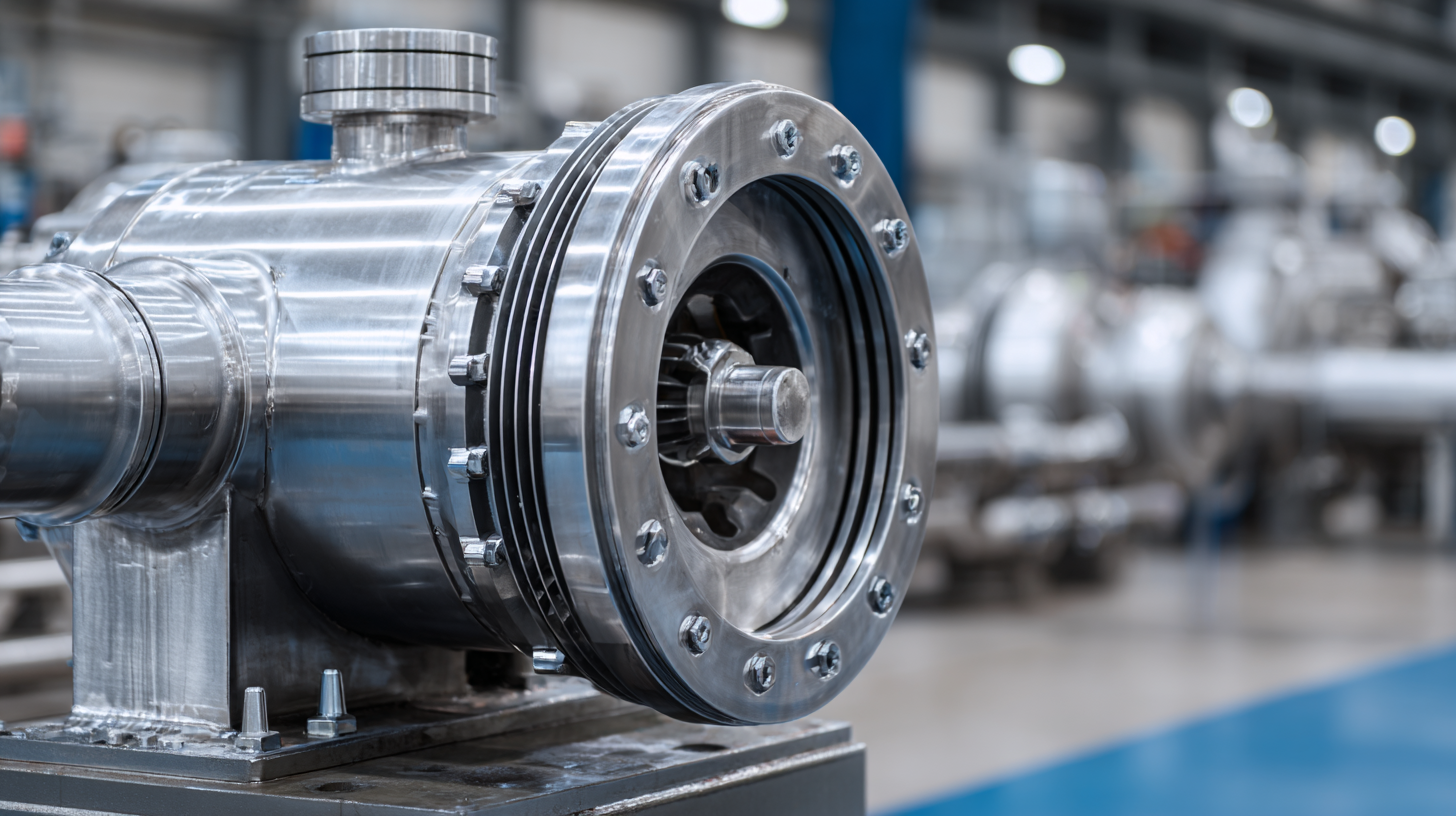

Recent innovations in diaphragm technology have introduced advanced materials that cater specifically to diverse applications, including wastewater management and the biopharmaceutical sector. For instance, air-operated diaphragm pumps now utilize innovative polymers that withstand aggressive chemicals, enhancing safety and reliability in corrosive environments. In biopharmaceutical manufacturing, single-use elastomers are gaining traction due to their convenience and reliability, minimizing contamination risks between production runs.

The market report indicates a projected growth of over 10% annually in single-use systems, further emphasizing the importance of selecting the right diaphragm materials tailored to each unique application.

When choosing the best pump diaphragm for your needs, it’s crucial to consider various import and export certifications that could affect your purchase. The recent RBI survey highlights that India's merchandise imports are set to grow at a pace twice that of exports in FY26, which indicates an increasing demand for foreign products, including industrial components like pump diaphragms. Ensuring compliance with international certification standards is vital for quality assurance and regulatory acceptance, especially in a global market undergoing significant shifts in trade dynamics.

One essential tip is to verify the certification authenticity of the manufacturer’s products. Check if the diaphragms meet the relevant quality standards, such as ISO certification or any specific industry regulations. Additionally, understanding the import tariffs imposed by countries, like the new U.S. tariffs that specifically target various goods, can influence your overall costs and trade strategy. Keeping informed about these developments will help you navigate the complexities of international trade while making informed decisions about sourcing the right pump diaphragm for your application.

When it comes to prolonging the lifespan of pump diaphragms, proper maintenance practices are crucial. According to a report by the Pumps & Systems Magazine, regular inspection and timely replacement of diaphragms can increase their operational lifespan by up to 30%. A critical factor influencing diaphragm longevity is material selection. For instance, diaphragms made of high-grade elastomers tend to outperform standard rubber variants, particularly in abrasive and harsh chemical applications. Utilizing the right diaphragms based on the specific working environment can thus significantly enhance performance and durability.

Another essential maintenance tip is the implementation of routine cleaning procedures. Build-up of contaminants can lead to premature wear and tear. The Hydraulic Institute suggests that cleaning diaphragms after every operational cycle can help mitigate damage from sediment and corrosive substances. Additionally, proper lubrication of moving parts, where applicable, ensures that diaphragms operate smoothly, reducing friction-related wear. Adopting these maintenance strategies not only enhances diaphragm lifespan but also contributes to overall pump efficiency, making it a worthwhile investment for any facility reliant on pump systems.