Leave Your Message

Request a Quote

Diaphragm pumps are widely recognized for their versatility and reliability in a variety of industries, including chemical processing, water treatment, and food production. According to the Global Diaphragm Pumps Market report, the sector is expected to witness a CAGR of 5.8% from 2022 to 2027, driven by increasing demand for efficient fluid transfer systems. To harness the full potential of diaphragm pumps, operators must prioritize maximizing their efficiency, as even minor adjustments can lead to significant cost savings and performance improvements. This article explores five essential tips that can dramatically enhance the operational efficiency of diaphragm pumps, ensuring they meet the growing industrial demands while minimizing downtime and maintenance costs. By understanding and implementing these strategies, businesses can optimize their pumping systems and maintain a competitive edge in the market.

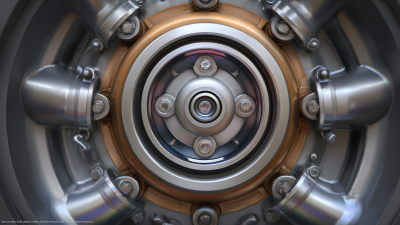

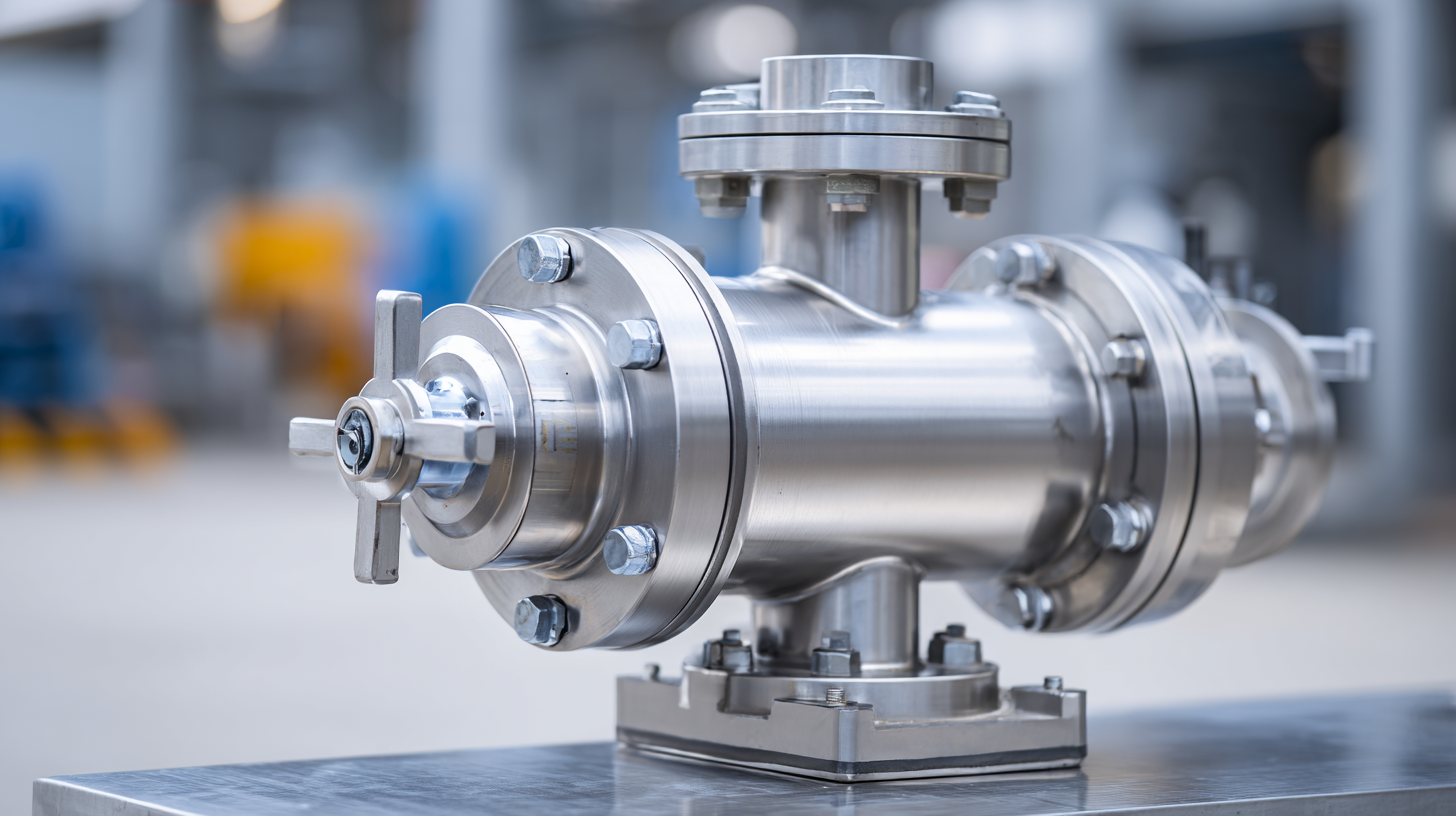

Diaphragm pumps play a critical role in various industries, including chemical processing, wastewater treatment, and construction. Understanding how these positive displacement pumps function is essential for achieving optimal performance. At their core, diaphragm pumps use a flexible membrane to create a vacuum that draws in fluid and then expels it, making them reliable for handling abrasive and corrosive materials. Familiarizing yourself with their operational principles can help users maximize their efficiency and lifespan.

To ensure effective operation, it’s vital to monitor flow rates, which can range significantly, depending on the model and application requirements. Proper maintenance, such as regularly checking for wear and tear on the diaphragm, is crucial to avoid unexpected downtimes and ensure a consistent output. Furthermore, understanding the importance of pressure settings and maintaining appropriate operational environments will enhance the reliability of these pumps. By mastering these fundamentals, users can position themselves to harness the full potential of diaphragm pumps in their respective operations.

This chart illustrates the efficiency of diaphragm pumps based on various operating conditions. The data reflects how flow rate and pressure affect overall performance, providing a visual representation of optimal usage parameters.

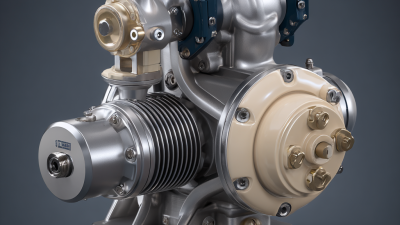

When selecting a diaphragm pump for your application, it’s crucial to avoid the common mistake of oversizing. An oversized pump not only leads to inefficiency but also increases operational costs and affects the overall performance of your system. To ensure you choose the right pump size and type, begin by thoroughly assessing the specific requirements of your application, including the flow rate, pressure, and the nature of the fluid to be pumped.

Additionally, understanding the differences between various pump types is vital. Diaphragm pumps, for example, are suitable for handling viscous and abrasive liquids, while centrifugal pumps might be more appropriate for low-viscosity fluids. By carefully evaluating these factors and avoiding the temptation to choose larger pumps than necessary, you can maximize the efficiency and longevity of your pumping system. Taking the time to make informed decisions will pay off in terms of improved performance and reduced maintenance costs.

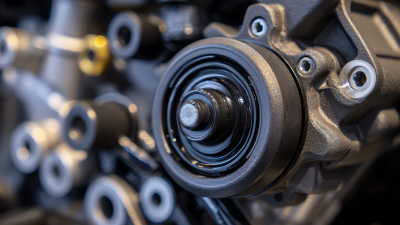

Regular maintenance practices are crucial for enhancing the longevity and efficiency of diaphragm pumps. First and foremost, routine inspection should be a fundamental part of your maintenance strategy. Checking for leaks, wear, and tear on the diaphragm and other components can prevent small issues from escalating into significant problems. Additionally, maintaining the proper lubrication of moving parts ensures smooth operation, reducing friction and wear, which can significantly extend the pump’s lifespan.

Another vital aspect of maintenance is the regular cleaning of the pump components. Accumulation of debris or contaminants can impede the pump's efficiency and lead to premature failure. By frequently cleaning the pump and its intake, operators can ensure optimal performance. Furthermore, it is essential to follow the manufacturer’s guidelines for parts replacement, particularly for diaphragms and seals, as these components are critical for the pump’s effective operation. Implementing these regular maintenance practices not only enhances pump efficiency but also promotes longevity, ultimately resulting in cost savings and reduced downtime.

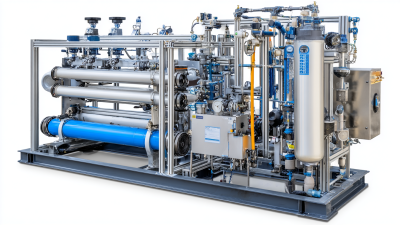

To truly optimize diaphragm pump efficiency, the first step is to ensure the pump setup is correctly aligned with the application requirements. According to a report by the Hydraulic Institute, proper alignment can reduce operational energy costs by up to 30%. Ensuring that the pump is correctly positioned and that all connections are tight can help in minimizing leaks, which not only waste resources but also compromise pump performance.

Another critical factor in configuration is selecting the right size and type of diaphragm pump. Research from the American Society of Mechanical Engineers suggests that improperly sized pumps can lead to inefficiencies, causing energy losses that account for as much as 20% of the total operational costs. Flow rates, pressure ratings, and material compatibility are essential considerations that must be carefully analyzed to achieve peak performance. Making data-driven decisions during the initial setup phase can significantly impact the longevity and effectiveness of the diaphragm pump system.

| Tip | Description | Expected Efficiency Improvement | Implementation Time |

|---|---|---|---|

| 1. Proper Sizing | Ensure the pump is appropriately sized for your application to avoid overworking. | 10-15% | 1 week |

| 2. Optimize Inlet Conditions | Minimize inlet pressure losses to improve flow rates. | 5-10% | 2-3 days |

| 3. Regular Maintenance | Conduct routine checks and maintenance to prevent downtime. | 15-20% | Ongoing |

| 4. Adjust Pump Speed | Change the pump speed according to the fluid characteristics for optimal performance. | 10-15% | Immediate |

| 5. Monitor Performance | Use monitoring tools to gather data and make informed adjustments. | Varies by setup | Ongoing |

Maximizing the efficiency of diaphragm pumps involves recognizing and addressing operational inefficiencies that can significantly affect performance. Common issues, such as air leaks and improper fluid viscosity, can reduce flow rates by up to 30%, as indicated by industry studies. Understanding the root causes of these inefficiencies is crucial for optimal operation. Regular maintenance checks and timely replacement of worn components can prevent common breakdowns that lead to downtime and increased operational costs.

Maximizing the efficiency of diaphragm pumps involves recognizing and addressing operational inefficiencies that can significantly affect performance. Common issues, such as air leaks and improper fluid viscosity, can reduce flow rates by up to 30%, as indicated by industry studies. Understanding the root causes of these inefficiencies is crucial for optimal operation. Regular maintenance checks and timely replacement of worn components can prevent common breakdowns that lead to downtime and increased operational costs.

Incorporating technology, such as AI, into the monitoring of diaphragm pumps can also help in identifying inefficiencies. Advanced data analytics allow for real-time performance tracking, enabling operators to anticipate potential failures and intervene before they result in significant disruptions. For instance, a recent survey conducted in the manufacturing sector highlighted that companies implementing digital solutions reported a 25% reduction in unexpected breakdowns. By integrating these strategies, operators can ensure smoother operations and significantly enhance the operational life of their diaphragm pumps.