Leave Your Message

Request a Quote

In the quest for improved water purification, the integration of innovative technologies has never been more crucial. One such advancement that stands out is the use of Membrane Filters, which have revolutionized the way we approach water treatment. These filters operate on the principle of selective permeability, allowing for the effective separation of contaminants from water, thus enhancing overall purification efficiency. As global water scarcity and pollution continue to pose significant challenges, understanding the capabilities and applications of Membrane Filter solutions is essential for both residential and industrial settings. This blog will delve into the latest advancements in membrane filtration technology, providing valuable tips to optimize its usage for maximum effectiveness in ensuring clean and safe drinking water. Join us as we explore how Membrane Filters can transform water purification methods, addressing both efficiency and sustainability in our efforts to combat the pressing water crisis.

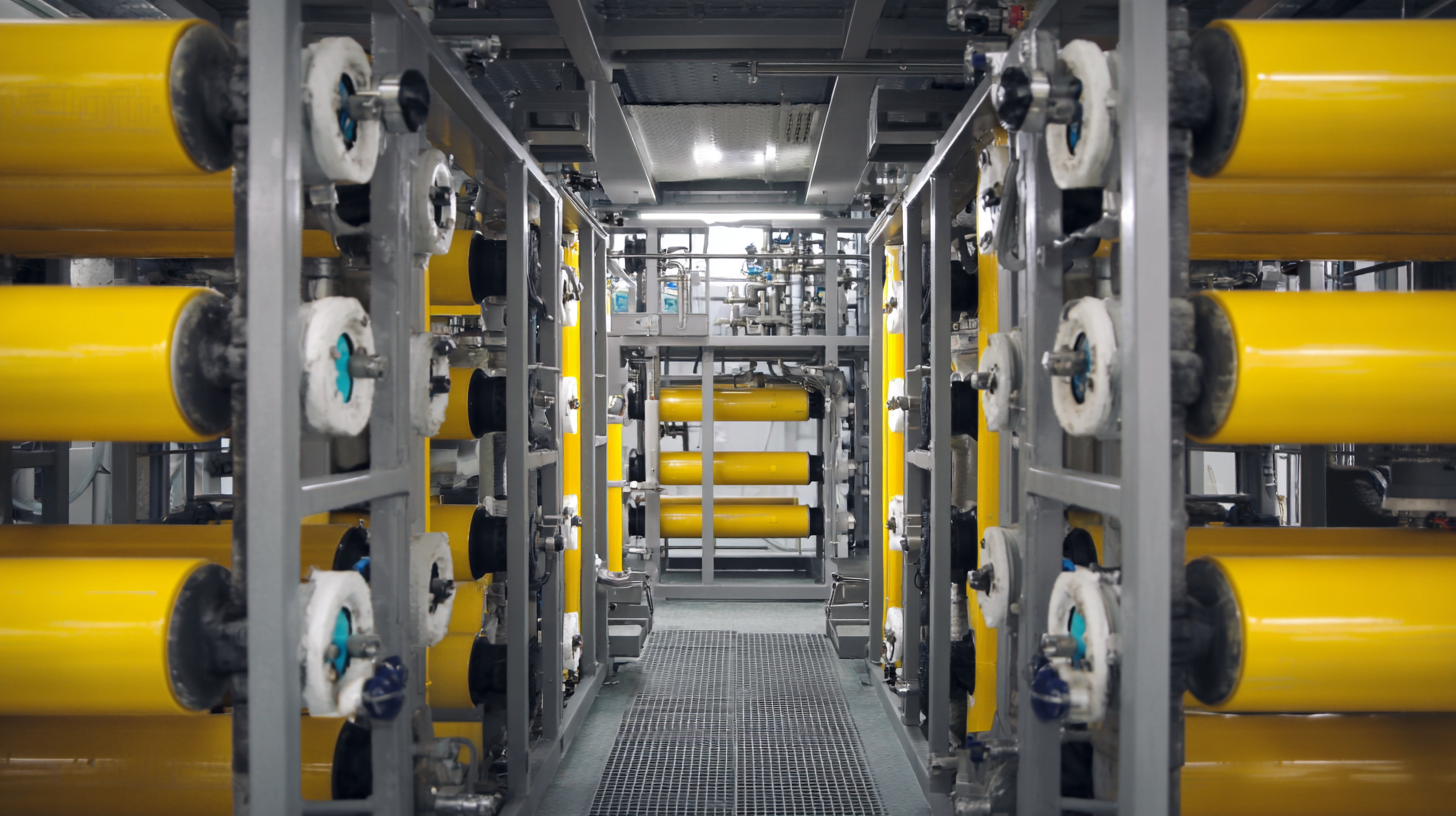

Membrane filtration technology is revolutionizing the water purification landscape by offering efficient and effective solutions for removing contaminants. Unlike traditional methods, membrane filters utilize semi-permeable barriers that allow water to pass through while blocking larger particles, pathogens, and impurities. This technology not only enhances the quality of water but also boosts the efficiency of purification systems, making them more sustainable and cost-effective in the long run.

The future of water purification lies in the continued innovation of membrane materials and designs. Advanced membranes, such as nanofiltration and reverse osmosis membranes, are being developed to target specific contaminants with greater precision. Additionally, researchers are exploring hybrid systems that combine membrane technology with other purification methods to maximize efficiency and reduce energy consumption. This integration represents a significant step forward in addressing global water challenges, ensuring access to clean and safe drinking water for communities around the world.

When it comes to enhancing water purification efficiency, choosing the right type of membrane filter is essential. The two most common types of membrane filters used in water treatment are microfiltration (MF) and ultrafiltration (UF). According to a report by MarketsandMarkets, the global membrane filtration market is projected to grow from USD 10.5 billion in 2020 to USD 16.3 billion by 2025, highlighting the increasing demand for advanced water treatment solutions. MF is effective for removing larger particulates and bacteria, while UF is designed to eliminate smaller contaminants, such as viruses and organic molecules, making it ideal for applications requiring higher purity levels.

Another important category is nanofiltration (NF), which operates between UF and reverse osmosis (RO). NF membranes are capable of removing divalent ions and larger organic molecules, making them suitable for softening water and removing color and trace pollutants. According to a study by the American Water Works Association, the use of NF can increase water recovery rates by up to 90%, providing significant efficiency advantages over traditional methods. Thus, when selecting a membrane filter, consider the specific contaminants present, desired purity levels, and overall system efficiency to ensure optimal water purification outcomes.

When it comes to water purification, membrane filtration systems are increasingly recognized for their efficiency and effectiveness. However, several key factors can significantly affect their performance. One of the foremost factors is the type of membrane material used. Different materials, such as polyamide or polysulfone, exhibit varying levels of permeability and fouling resistance, which can influence the overall filtration process. The choice of membrane not only determines the size of contaminants that can be filtered but also affects the longevity and maintenance costs of the system.

When it comes to water purification, membrane filtration systems are increasingly recognized for their efficiency and effectiveness. However, several key factors can significantly affect their performance. One of the foremost factors is the type of membrane material used. Different materials, such as polyamide or polysulfone, exhibit varying levels of permeability and fouling resistance, which can influence the overall filtration process. The choice of membrane not only determines the size of contaminants that can be filtered but also affects the longevity and maintenance costs of the system.

Another critical factor is the operational conditions under which these systems run. Parameters such as pressure, temperature, and flow rates are crucial, as they can optimize or hinder the filtration efficiency. For instance, higher pressure can increase flow rates but may also lead to quicker fouling of the membrane, requiring more frequent cleaning or replacement. Additionally, pre-treatment processes like sedimentation or coagulation can enhance membrane performance by removing larger particulate matter, thereby increasing the lifespan of the membranes and improving permeate quality. Understanding and optimizing these factors is essential for maximizing water purification efficiency in membrane systems.

Maintaining membrane filters is crucial for ensuring optimal water purification performance. Regular inspection of the filters plays a significant role in identifying any signs of wear and tear, such as fouling or scaling, which can significantly decrease efficiency. It is advisable to develop a routine maintenance schedule that includes cleaning the membranes to remove accumulated contaminants. Utilizing appropriate cleaning solutions and methods tailored to the specific type of membrane can significantly prolong its lifespan and enhance its performance.

In addition to regular cleaning, monitoring pressure differentials across the membrane is essential. A significant increase in pressure may indicate blockage or fouling, necessitating immediate attention. Implementing proper pre-filtering systems can also reduce the load on the membrane filters by removing larger particles that could contribute to fouling. Furthermore, staff training on the best practices for operating and maintaining membrane systems is vital to maximize their efficiency and reliability in water purification applications. By adhering to these maintenance guidelines, users can achieve optimal membrane filter performance and ensure a sustainable source of purified water.

Innovations in membrane technology are transforming the landscape of water purification, paving the way for sustainable treatment solutions. Recent advancements have unlocked the potential for membranes that not only improve filtration efficiency but also reduce energy consumption and operational costs. Enhanced materials, such as graphene and nanomaterials, are being utilized to create membranes with superior permeability and selectivity, leading to faster processing times and increased water recovery rates. These innovations are essential in addressing global water scarcity challenges.

**Tip:** Consider investing in systems that incorporate the latest membrane technologies, as they often provide long-term savings and better environmental outcomes. Regular maintenance is also crucial; ensuring membranes are cleaned appropriately can prolong their lifespan and maintain efficiency.

Moreover, the integration of smart technologies into membrane filtration systems offers real-time monitoring and optimization of the purification process. This innovation allows for immediate adjustments based on the quality of the water being treated, enhancing overall system responsiveness. As the water treatment industry evolves, the focus on sustainable practices will drive further innovations in membrane filtration.

**Tip:** Explore solutions that offer automated monitoring capabilities, which can simplify operations and enhance decision-making. Being proactive in maintenance and upgrades will ensure your water treatment systems remain efficient and effective.

| Membrane Type | Pore Size (µm) | Material | Filtration Efficiency (%) | Application | Sustainability Feature |

|---|---|---|---|---|---|

| Microfiltration | 0.1 - 10 | Polymeric | 90 | Pre-treatment for reverse osmosis | Recyclable materials |

| Ultrafiltration | 0.01 - 0.1 | Ceramic | 95 | Water recovery systems | Long-life durability |

| Nanofiltration | 0.001 - 0.01 | Polyamide | 98 | Softening and removal of contaminants | Energy-efficient operation |

| Reverse Osmosis | <0.001 | Thin-film composite | 99 | Desalination | Low wastewater generation |

| Forward Osmosis | Variable | Specialized polymer | 90 | Wastewater treatment | Uses natural osmotic pressure |