Leave Your Message

Request a Quote

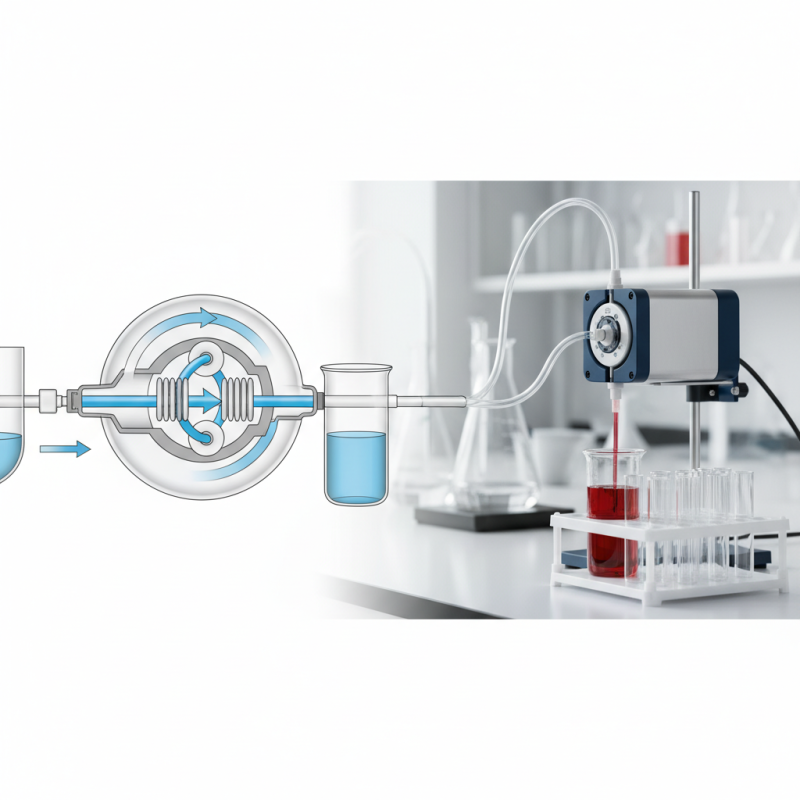

A peristaltic pump is a unique type of positive displacement pump that operates by utilizing the rhythmic contraction and relaxation of a flexible tube. This mechanism mimics the natural processes found in living organisms, making it particularly effective for transferring fluid in various applications, including medical, laboratory, and industrial settings. Unlike traditional pumps, which may pose contamination risks, a peristaltic pump ensures that the fluid only comes into contact with the tubing material, thus maintaining a sterile environment and preventing contamination.

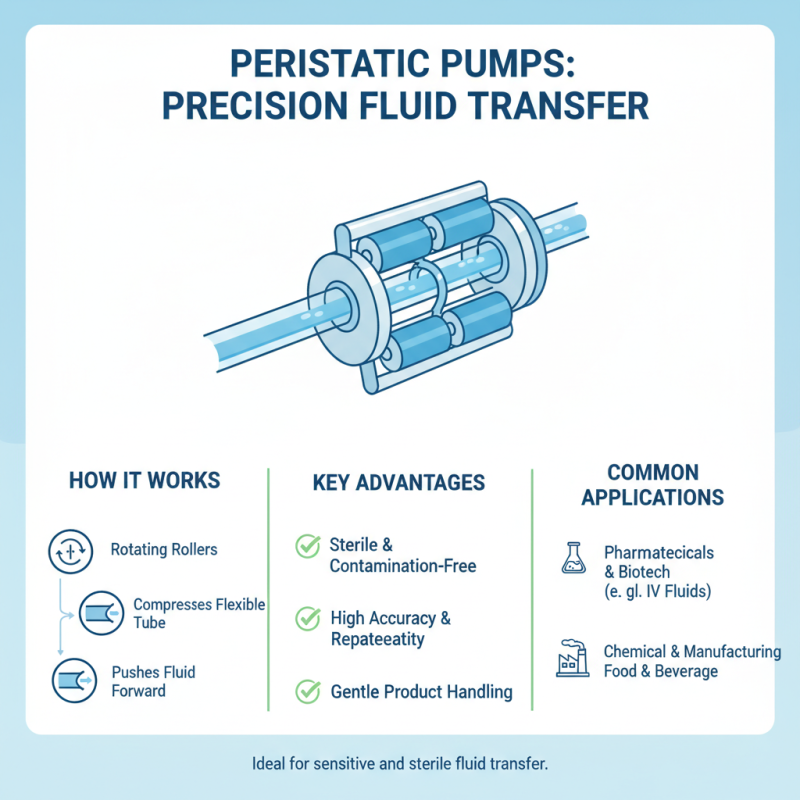

The fundamental design of a peristaltic pump involves a rotating mechanism that compresses the tubing at specific points, creating a vacuum that draws the fluid into the tube. As the mechanism continues to rotate, the compression moves along the tube, pushing the fluid forward in a smooth, continuous flow. This gentle pumping action makes the peristaltic pump particularly advantageous for handling shear-sensitive fluids, such as biological samples or viscous materials.

In summary, understanding how a peristaltic pump works is crucial for industries that require precise fluid handling and management. Its ability to provide reliable, contamination-free fluid transfer makes it an invaluable tool in an array of fields, underscoring its importance in modern fluid dynamics.

A peristaltic pump is a type of positive displacement pump that moves fluids through a tube by creating a series of wave-like motion. This mechanism mimics the natural muscle contractions seen in biological systems, such as the esophagus. The core components include a rotor and a set of rollers that compress the tubing, creating a vacuum that draws fluid into the pump. As the rollers move, they sequentially create and release pressure on the tubing, propelling the fluid forward without it coming into contact with any moving parts, making this system highly efficient for various applications.

According to a report by Research and Markets, the global peristaltic pump market is projected to grow significantly, reaching approximately $2.2 billion by 2024. This substantial growth is driven by increased demand in sectors like pharmaceuticals, food and beverage, and wastewater treatment. The inherent design of peristaltic pumps allows for accurate dosing, minimal shear stress, and the ability to handle viscous materials, which are critical attributes for industries where purity and precision are paramount. Their versatility and ease of maintenance further solidify their position as essential equipment in many production processes.

A peristaltic pump operates on a simple yet effective principle that mimics the natural movement of peristalsis in the human digestive system. This type of pump consists of several key components that work together to ensure smooth fluid transfer. The primary elements include a flexible tube, which acts as the fluid pathway; a rotor that carries multiple rollers or shoes; and a stationary casing. As the rotor turns, the rollers compress the tube at various points, creating a vacuum that draws fluid into the tube and subsequently pushing it forward as the compression is released.

The flexible tubing is critical, as it not only needs to withstand the pressure of the fluid but also must be resistant to the chemical properties of the media being pumped. Industry reports indicate that the material used for these tubes, often silicone, can significantly affect the lifespan of the pump. Furthermore, the choice of tubing diameter directly impacts flow rates, with smaller diameters offering precision in low-flow applications while larger diameters can manage higher volume needs. According to a report by MarketsandMarkets, the global peristaltic pump market is anticipated to reach USD 600 million by 2025, driven by advancements in medical diagnostics and biotechnology sectors, further emphasizing the necessity of quality components in pump construction.

Another essential aspect of a peristaltic pump is its ease of maintenance. Since the fluid does not come into contact with the mechanical parts, the pump is often self-priming and can be cleaned or replaced without significant downtime. This feature is particularly valuable in industries such as pharmaceuticals and food processing, where contamination control is imperative. Reports have noted that the maintenance costs for peristaltic pumps can be up to 30% lower than traditional pumps, making them an attractive option for many applications.

Peristaltic pumps operate based on a simple yet effective mechanical principle. The core mechanism consists of a rotor fitted with several rollers or shoes that compress and decompress a flexible hose or tube. As the rotor turns, it creates a series of waves that push the fluid through the tube. This method of fluid movement not only minimizes contamination risks, as the fluid never comes into contact with the pump's moving parts, but it also allows for accurate dosing, which is critical in industries such as pharmaceuticals and food processing.

According to a recent market analysis report, the demand for peristaltic pumps is projected to grow at a CAGR of 6.5% from 2021 to 2028, highlighting their importance in various applications including fluid transfer and metering in sectors such as biotechnology, water treatment, and chemical processing. The design also facilitates easy maintenance, as replacing the tubing can often be done without the need for specialized tools or technical knowledge, making these pumps an efficient choice for continuous operation.

Tips: When using peristaltic pumps, always ensure to select a tubing material compatible with your fluid to prevent degradation. Additionally, regularly checking for wear and tear in the tubing can prolong the service life of the pump and maintain operational efficiency.

Peristaltic pumps are essential tools across various industries due to their unique method of fluid handling. In the pharmaceutical and biotechnology fields, these pumps are commonly used for the sterile transfer of fluids. Their mechanism, which involves squeezing a flexible tube, ensures that the liquid being pumped does not come into contact with the pump components, minimizing the risk of contamination. This feature makes them ideal for applications that require high precision and cleanliness, such as intravenous fluid administration.

In the food and beverage industry, peristaltic pumps play a crucial role in processes like ingredient dosing, transferring viscous products, and bottling operations. Their gentle pumping action is particularly beneficial for handling delicate products, such as fruit juices and sauces, as it prevents damage to the fluid structure and maintains product integrity. Furthermore, their ease of cleaning helps meet stringent hygiene standards, making them suitable for a wide range of consumables.

The chemical processing sector also relies on peristaltic pumps for their ability to handle aggressive fluids, including acids and solvents. These pumps can operate in harsh environments without the risk of leakage, thanks to their closed-system design. Additionally, they offer the flexibility of transferring varying viscosities, making them versatile tools in managing different chemical formulations. As industries continue to prioritize efficiency and safety, peristaltic pumps remain a dependable choice for fluid management across various applications.

Peristaltic pumps are widely used in various industries due to their unique mechanism, which utilizes flexible tubes to move fluids through a series of compressions and relaxations. This mechanism offers several advantages. Firstly, peristaltic pumps are highly accurate in dosing, making them ideal for applications that require precise fluid control, such as laboratories and pharmaceutical manufacturing. Additionally, their design allows for easy maintenance since the only component that comes into contact with the fluid is the tubing, which can be easily replaced without needing to disassemble the entire pump.

However, there are also some disadvantages to consider. One significant drawback is that peristaltic pumps tend to have a lower flow rate compared to other types of pumps, which may not be suitable for high-volume applications. Furthermore, the tubing can wear out over time due to the constant flexing and can be affected by the properties of the fluid being pumped, such as viscosity and temperature. This could lead to increased operational costs if tubing needs to be replaced frequently. In summary, while peristaltic pumps offer precision and ease of maintenance, their limitations in flow rate and tubing durability should be carefully considered when selecting a pumping solution.

| Dimension | Data |

|---|---|

| Pump Type | Peristaltic Pump |

| Common Applications | Fluid transfer, Medical devices, Chemical processing |

| Advantages | Gentle pumping action, Self-priming, High accuracy |

| Disadvantages | Limited pressure capabilities, Wear on tubing, Higher maintenance |

| Fluid Compatibility | Viscous, Shear-sensitive fluids |

| Typical Flow Rate | Up to 1000 L/h (dependent on design) |

| Maintenance Frequency | Every few months, depending on usage |