Leave Your Message

Request a Quote

Peristaltic pumps have become vital in numerous industries. These pumps are known for their precise fluid handling capabilities. A recent market report indicates a steady growth rate of 5.3% annually in the peristaltic pump sector. Such growth reflects an increased reliance on accurate fluid transfer in various applications.

The versatility of peristaltic pumps is evident in sectors like agriculture, food, and pharmaceuticals. These pumps safely move sensitive materials without contamination risks. For example, the pharmaceutical industry often uses peristaltic pumps for sterile fluid transfer. However, some users report issues with wear and tear on tubing. This indicates a need for careful material selection.

As innovations emerge, understanding the top models available is crucial. The 2026 lineup promises enhancements in efficiency and reliability. Selecting the right peristaltic pump model can impact operational success significantly. Ignoring essential factors, such as application needs and maintenance, can lead to suboptimal performance. An informed choice is indispensable in this evolving landscape.

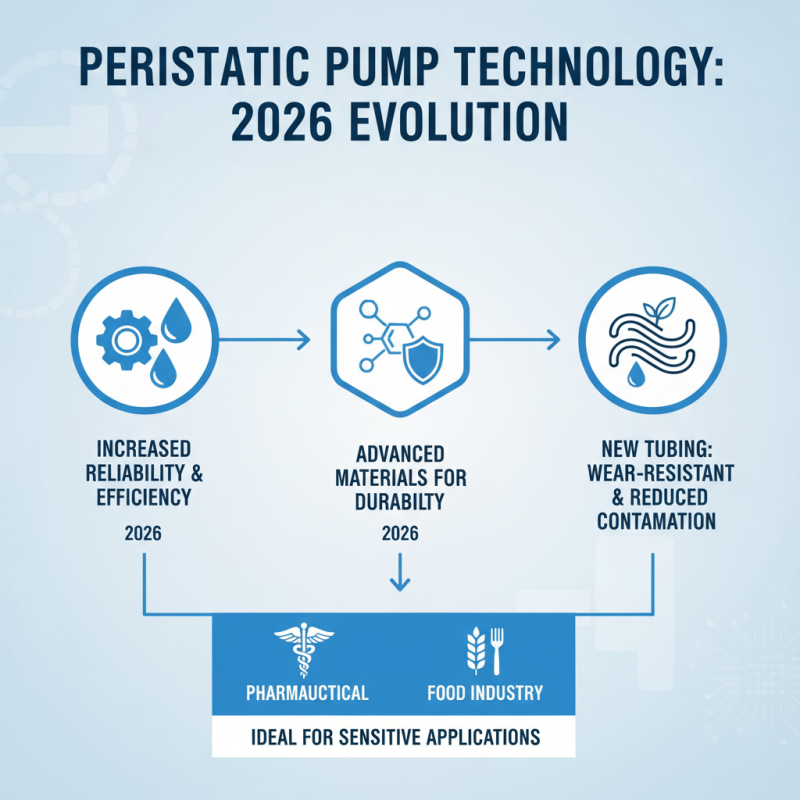

The evolution of peristaltic pump technology is captivating. In 2026, these pumps have become more reliable and efficient. Recent advancements focus on materials that enhance durability. New tubing options resist wear and reduce contamination risks. This makes them suitable for sensitive applications in pharmaceuticals and food industries.

With improved control systems, peristaltic pumps now offer better accuracy. Digital interfaces allow for real-time monitoring. This fosters precision in fluid handling tasks. Some users, however, may find the learning curve steep. Not all facilities are equipped to handle these innovations effectively.

While the new designs promise enhanced performance, challenges remain. Issues with compatibility can arise with existing equipment. Upgrading systems without compromising production can be tricky. As industries embrace these advancements, ongoing discussions about usability will be essential. Flexibility is key to truly capitalize on the technology's potential.

In various industries, peristaltic pumps play a crucial role. They are known for their ability to handle delicate liquids without contamination. This makes them suitable for the food and beverage sector, where hygiene is paramount. These pumps ensure that the product remains pure and safe for consumption.

In the pharmaceutical industry, precise dosing is essential. Peristaltic pumps excel in this area, providing accurate flow rates. They can handle shear-sensitive compounds, which is often a challenge. This capability helps in maintaining the integrity of active ingredients. Moreover, the pumps are easy to maintain, which is a major advantage in a fast-paced production environment.

The chemical industry also benefits greatly from these pumps. They are capable of transporting corrosive fluids safely. However, the durability of the tubing is crucial. Over time, wear and tear can create issues. Regular checks and replacements are necessary to avoid downtime. This is a point of reflection for many companies using these systems. Each sector can leverage peristaltic pumps, but they must consider the specific requirements of their applications.

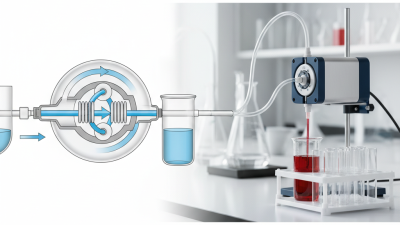

Peristaltic pumps play a crucial role in the pharmaceutical industry. These pumps offer precise fluid transfer, essential for accurate dosing. They operate based on a simple mechanism of squeezing flexible tubing. This design minimizes contamination risks, a significant concern in pharmaceutical manufacturing.

Due to their versatility, peristaltic pumps are used in various applications. They are ideal for handling sensitive materials, such as cell cultures and enzymes. The gentle peristaltic action prevents damage to these delicate substances. However, the selection of tubing is vital. Poor quality tubing can lead to inconsistent flow rates and increased risk of leaks.

Additionally, maintenance is required to ensure optimal performance. Regular inspection of the pump and tubing can prevent potential breakdowns. Operators must pay attention to wear and tear. Ignoring these aspects may affect production quality. Balancing efficiency with thorough checks is necessary in pharmaceutical operations.

Peristaltic pumps play a crucial role in food and beverage processing. They are designed to handle delicate liquids without causing damage. These pumps work by creating a rhythmic squeezing action. This ensures a gentle transfer of liquids, reducing foaming and shear stress.

In food and beverage applications, sanitation is critical. Peristaltic pumps are easy to clean and maintain. Their simple design allows for quick disassembly. This helps prevent contamination, a significant concern in the industry. Additionally, they can handle various viscosity levels. This versatility makes them ideal for different types of products.

However, challenges exist. Pump wear can occur, affecting performance. Regular maintenance is needed to ensure reliability. Sometimes, users overlook the importance of monitoring flow rates. This can lead to inconsistent product quality. Being mindful of these aspects can enhance the efficiency of processes in food production.

Maintaining modern peristaltic pumps is crucial for optimal performance. These pumps work by contracting and relaxing a flexible tube to move fluid. Regular maintenance ensures longevity and efficiency. Checking the tubing is vital. Worn tubes can lead to leaks and reduced flow accuracy. Inspections should occur frequently, ideally every month.

Efficiency can fluctuate without proper care. Dust and debris can accumulate, impacting the pump's function. Simple cleaning routines can mitigate this. Operators should also monitor operating conditions. Temperature and pressure variations can stress the system. Adjusting these factors can enhance performance and reduce wear.

Feedback from operators often reveals overlooked areas. For instance, sometimes, users forget to replace tubing on schedule. This can lead to unexpected failures. Regular training is essential. Knowing when to act is part of maintaining these pumps effectively. Continuous improvement in maintenance practices will keep peristaltic pumps running smoothly.

| Model | Flow Rate (L/min) | Max Pressure (bar) | Tubing Material | Applications | Maintenance Frequency |

|---|---|---|---|---|---|

| Model A | 0.5 - 5 | 2.0 | Silicone | Food Processing | Quarterly |

| Model B | 1 - 10 | 2.5 | PVC | Chemical Transfer | Monthly |

| Model C | 5 - 15 | 3.0 | Santoprene | Pharmaceuticals | Biannually |

| Model D | 0.8 - 8 | 2.0 | EPDM | Water Treatment | Sem annually |